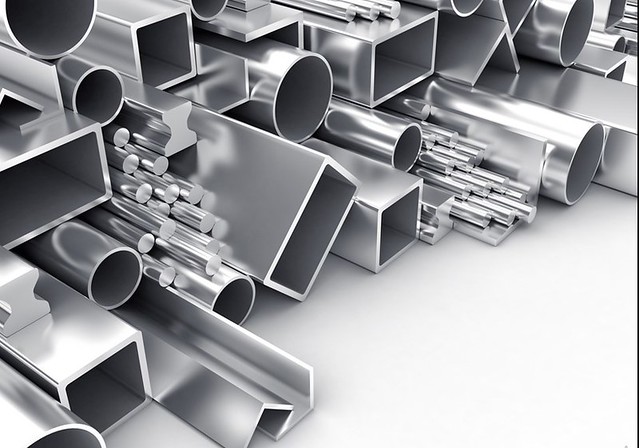

Steel Pipe/Tube

Manufacturing Process, Features, Advantages, Usage Methods, How to Choose the Product, Conclusion.

Steel pipes/tubes are an essential component used in various industries for transportation of fluids and gases. They are widely used in plumbing sy Metallic piping stems, oil and gas pipelines, construction projects, and industrial applications. In this article, we will explore the manufacturing process of steel pipes/tubes

, their characteristics and advantages over other materials, how they can be used effectively and how to choose the right product for your needs.

The manufacturing process of steel pipes/tubes involves several steps. First is the selection of appropriate raw materials. Carbon steel casing is commonly used due to its high strength and durability. It provides excellent resistance against corrosion and can withstand extreme temperatures.

Seamless steel cylinders are produced through a process called seamless pipe making. This method ensures uniformity in thickness Steel Pipe/Tube throughout the pipe/tube resulting in better structural integrity. Seamless pipes are known for their superior mechanical properties as they do not have any welded joints that could weaken them.

Anoth Carbon steel casing er type of metallic piping commonly used is welded steel pipe/tube . These pipes consist of multiple sections joined together using welding techniques such as electric resistance welding or submerged arc welding.

Round Steel plays a crucial role in shaping these tubes/pipes into different sizes and specifications. The round shape allows for easy Steel Pipe/Tube bending without compromising its structural strength.

Now let’s discuss some key features that make steel pipes /tubes stand out from other materials:

1) Durability: Steel has impressive mechanical properties which makes it highly resistant to wear-and-tear.

2) Strength: Steel possesses exceptional tensile strength which enables Seamless steel cylinder it to withstand heavy loads.

3) Corrosion Resistance: With proper coating or material selection ,steel tubes/pipes exhibit high resistance towards rusting,making them ideal choices for outdoor applications even under harsh environments.

4) Versatility: Steel can be easily fabricated into various shapes,sizes and specifications,meeting the specific demands of different industries.

The advantages offered by steel pipes

/tubes include cost-effectiveness, long service life, and low maintenance requirements. They are also eco-friendly as they can be recycled and reused for multiple purposes.

In terms of usage, steel pipes/tubes find applications in a wide range of industries such as oil and gas, water supply systems ,construction projects etc .They are used for transporting fluids like water,oil,gas or even solid materials like grains.For industrial applications,the pipes need to withstand high pressure or ext Round Steel reme temperatures.The durability and strength provide Round Steel d by steel ensures that it meets these rigorous demands.

When selecting steel pipe/tube products ,consider the following factors:

1) Size and thickness: Ensure that you choose the right dimensions for your specific application.

2) Material composition: Carbon Steel is commonly used due to its balance between strength,resistance against corrosion,and affordability.

3) Manufacturing process:Bear in mind the manufacturing methods- seamless or welded-to ensure it fulfills your project requirements .

4) Standard Steel Pipe/Tube s compliance: Make sure the product adheres to relevant industry standards. For example,American Petroleum Standard (API),American Society of Mechanical Engineers (ASME).

5)Cost considerations: Evaluate cost- Steel Pipe/Tube effectiveness over long-term use while considering initial investment vs maintenance costs

To summarize, steel pipes/tubes are an indispensable component in various industries due to their excellent mechanical properties and versatility. Whether it’s carbon steel casings for plumbing systems or seamless cylindrical tu

bes for construction projects – there is a diverse range available catering to every need. By understanding the manufacturing process, key features, advantages,and usage methods along with careful consideration when choosing a product,you can ensure optimal performance,reliability,safety,and longevity in your applications.