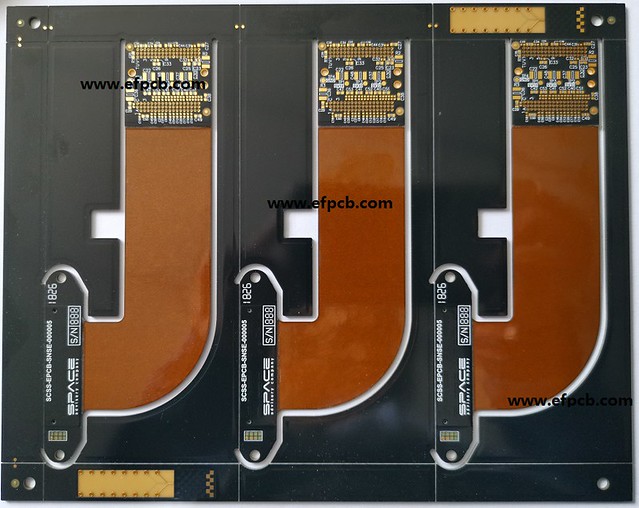

Title: The Versatility of Flexible PCBs

Flexible printed circuit boards (PCBs) have revolutionized the world of electronics with their unique capabilities and applications. Also known as elastic printed wiring

boards or soft PCBs, flexible PCBs offer a myriad of advantages over traditional rigid PCBs. These ligh High Frequency PCB tweight and highly flexible circuits are widely used in various industries such as automotive, medical devices, aerospace, and consumer electronics.

Manufacturing Process:

Flexible PCBs are typically made using polyimide or polyester film as the base materi Flexible PCB al. The manufacturing process involves etching copper traces on the substrate to create the desired circuit pattern. Unlike rigid PCBs that use fiberglass for insulation, flexible PCBs utilize materials that allow for bending and twisting without compromising performance.

Features:

One of the key features of flexible PCBs is their flexibility, which enables them to fit into compact spaces where rigid boards cannot be utili Rigid-flex PCB zed. This makes them ideal for applications that require intricate designs or space-saving solutions. Addit PCB manufacturer ionally, flexible PCBs are lighter in weight and more resistant to vibrations and mechanical stress compared to rigid boards.

Advantages:

The main advantage of using a flexible PCB is its ability to reduce overall sys Flexible printed circuit board tem size and weight while improving reliability. By eliminating connectors and reducing assembly time, manufacturers can achieve cost savings in production. Furthermore, flexible circuits offer excellent signal integrity du

e to reduced electromagnetic interference (EMI) issues.

Usage:

Flexible circuits can be found in a wide range of products including smartphones, smartwatches, medical implants, automotive sensors,

and aerospace equipment. Their adaptability allows designers to incorporate complex electronic functions into small form factors without sacrificing performance.

How to Choose Flexib Flexible PCB le PCBFlexible?

When selecting a Flexible PCBFlexible board manufacturer it is important

to consider factors such as expertise in designing flex circuits,

quality control processes,Flexible PCBFlexible,

production capabilities,and customer suppo Soft PCB rt.

Additionally,opting for high frequencypcb(Flex Circuit)

orrigid-flex pcboptions may be beneficial depending onthe application requirements.

Conclusion:

In conclusion,FlexiblePCBs(PCB)offerunparalleledflexibilityandversatilityinthe fieldofelectronicsmanufactur Flexible PCB ing.Withtheiruniquefeaturesandadvantages,t heseinnovativecircuitscontinue togainpopularityacrossvariousindustries.Theyhavebecomeanessentialcomponentinthesuccessofmodern electronicdevicesandarepoisedtoreshape futuretechnological advancements.Forsuperiorperformanceandreliability,itisevidentthatFlexCircuitsholdthepromise Elastic printed wiring board forth unfathomablepossibilitiesintheworldoftomorrow.