Flexible PCB: Revolutionizing Electronics

Introduction:

In t

oday’s rapidly advancing technology landscape, flexible PCBs (Flex PCB) have emerged as a game-changing innovation. This article aims to explore the manufacturing process, characteristics, advantages, and usage methods of Flex PCBs. Additionally, it will provide valuable insights on how to choose the right product for specific applications.

Manufacturing Process:

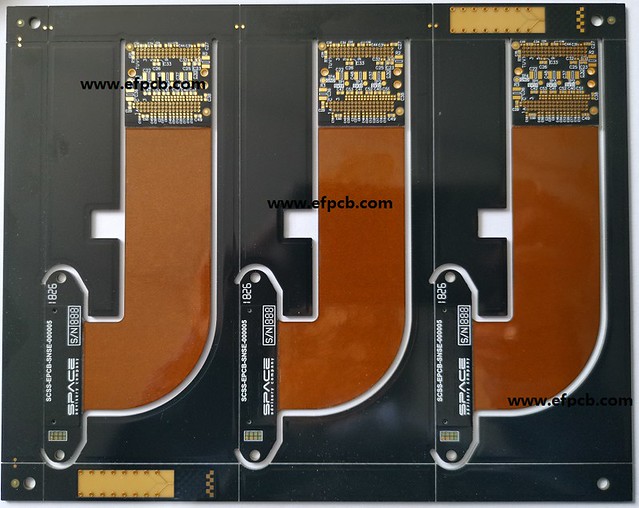

Flexible electronic circuit boards are manufactured using a specialized technique called “flexible printed circuit board” (FPCB). The process involves printing conductive pathways on polyimide or polyester film substrates. These flexible substrates allow bending and conforming to fit different shapes and designs. Through an intricate combinat Flex PCB ion of etching, lamination, drilling, plating, and assembly processes—Flex PCBs are brought to life.

Characteristics:

Flex PCBs possess several notable characteristics that di High Frequency PCB fferentiate them from traditional rigid-based counterparts:

1. Bendability: Unlike rigid boards limited by their fixed form factor,

Flexible PCBFlexible PCB enables designers to incorporate complex 3D curves or foldings into their electronics.

2. Space Efficiency: The ability of Flex PCBs to be flexed or folded allows for optimal space utilization within increasingly miniaturized devices.

3. Lightweight: Flexible circuit boards eliminate bulky connectors found in traditional wiring setups due to its integrated design.

4. High Temperature R Rigid-flex PCB esistance: With enhanced dielectric properties of advanced materials, Flex PBC can withstand higher operating temperatures compared to traditional circuits.

Advantages:

The advent of flexible printed circuit boards has revolutionized various industries due to their numerous benefits:

1.Increased Reliability: As there are no physical connectors involved in Flex PBC,Flexibility PCBF,the need for solder joints is eliminated; this enhances r Flexible electronic circuit board eliability by reducing failure points.

2.Simple Assembly Process:FPCBs offer simplified assembly procedures resulting in improved production efficiency while reducing cost overhead.

3.Cost-Effective Design Modifications:The flexibility offered by Flex PCBs enables easier de Flexible PCB sign iterations, modifications, and even post-production changes—a significant advantage in the ever-evolving technology landscape.

Use Cases:

Flexible printed circuit boards are finding applications across diverse industries:

1.Consumer Electronics: From smartphones to wearable devices to flat-screen televisions, Flex PBC facilitates seamless integration into space-constrained consumer electronics.

2.Aerospace and Automotive: The lightweight nature and high temperature resistance make FPCBs ideal for aerospace and automotive ap Flexible PCB plications where size, weight reduction,and performance reliability are critical factors.

3.Medical Devices: Flex PCBFlexibility PCB is used ext

ensively in medical devices due to its ability to conform to complex shapes while maintaining electrical connectivity. Examples include pacemakers, hearing aids,iOSdian Diagnostic units etc.

How to Choose the Right Product:

When selecting a flexible printed circuit board manufacturer, consider the following criteria:

1.Experience:The manufacturer’s track reco Flexible printed circuit board rd of producing reliable flexible circuits.Rigid-flex PCBS may also be considered if required by your application.

2.Quality Standards:Adherence to international quality standards like ISO 9001 ensures consistent product quality throughout manufacturing processes.

3.Durability:Determine if the chosen product offers appropriate durability in terms of ben PCB manufacturer ding cycles or harsh environment operations based on your specific requirements.

4.Technical Support:A reliable manufacturer should provide technical guidance during product selection and offer responsive support services when needed.

Conclusion:

The rise of flexible PCBs has disrupted conventional methods of designing electronic products. Their unique characteristics—bendability, space efficiency,and high temperature resista Flexible PCB nce—make them increasingly popular across various industries. By choosing an experienced manufacturer that adheres strictly to quality standards,you can leverage these advantages effectively.Attempting creative designs that were once deemed impossibleis now made possible by harnessing the capabilitiesof this revolutionary technology