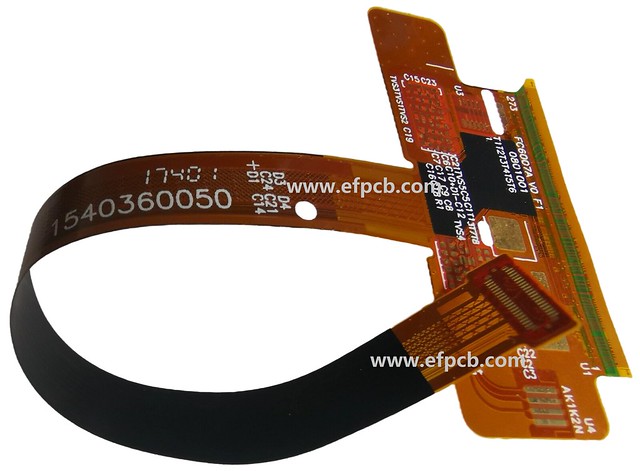

Flexible PCB: A Versatile Solution for Advanced Circuitry

In the ever-evolving world of electronics, innovation is the key to success. One revolutionary technological advancement that has taken the industry by storm is the Flexible Printed Circu Flexible electronic circuit board it Board (Flex PCB). This flexible electronic circuit board offers a myriad of possibilities and has become an essential component in m Rigid-flex PCB any cutting-edge devices.

Manufacturing Method:

Flexible PCBs are made using specialized materials and manufacturing processes. These boards are typically crafted from thin layers of polyimide or similar flexible substrates. The process starts with etching copper patterns onto the substrate material, followed by laminating multiple layers toge PCB manufacturer ther. This intricate procedure creates a compact yet highly reliable circuitry that can withstand bending and flexing without compromising performance.

Characteristics:

Flex PCBs possess sever Flexible printed circuit board al unique characteristics that set them apart from their rigid counterparts. Firstly, they provide exceptional flexibility, allowing them to conform to irregular shapes and fit into tight spaces where traditional circuit boards cannot be used effectively. Secondly, these boards exhibit excellen

t thermal stability under challenging conditions, making them suitable for high-temperature applications. Moreover, due to their lightweight nature and reduced size requirements compared to conventional PCBs, Flex PCBs offer significant space-saving adv Flexible PCB antages.

Advantages:

The use of Flexible Printed Circuit Boards brings forth numerous benefits in various industries. Their bendable printed circuitry enables seamless integration into wearable devices such as smartwatches and fitness trackers. The flexibility aspect also proves advantageous in automotive applications where curved surfaces need customized electronic systems implementation. Additionally, Flex PCBs are highly resistant to vi High Frequency PCB brations and shock because they lack solder joints which tend to weaken over time on rigid boards.

Usage Methods:

To utilize a Flexible PCB effectively, one must consider certain factors during design and assembly stage Flexible PCB s. It’s crucial to determine appropriate bending angles required by considering components’ specifications while ensuring proper signal integrity throughout flexing cycles.

Furthermore,

Choosing the Right Product:

Selecting a reliable manufacturer is vital when it comes to Flexible PCBs. A well-equipped PCB Flexible PCB manufacturer specializing in Flex and Rigid-Flex solutions will offer a wide range of choices, including High-Frequency PCB options for enhanced performance. It’s important to assess their manufacturing capabilities, quality control

processes, and track record in delivering superior products.

Conclusion:

In conclusion, the advent of Flexible Printed Circuit Boards has revolutionized the electronics industry by providing an unparalleled level of versatilit

y and reliability. Their unique characteristics enable custom designs that were previously unimaginable with rigid circuit boards. Whether it’s for advanced medical devices or consumer electronics, Flex PCBs offer a flexible solution capable of meeting the most demanding applications’ requirements. B Bendable printed circuitry y selecting a reputable manufacturer and understanding proper usage methods, one can harness the full potential of this groundbreaking technology.