Title: A Comprehensive Guide to Multilayer PCBs

Introduction

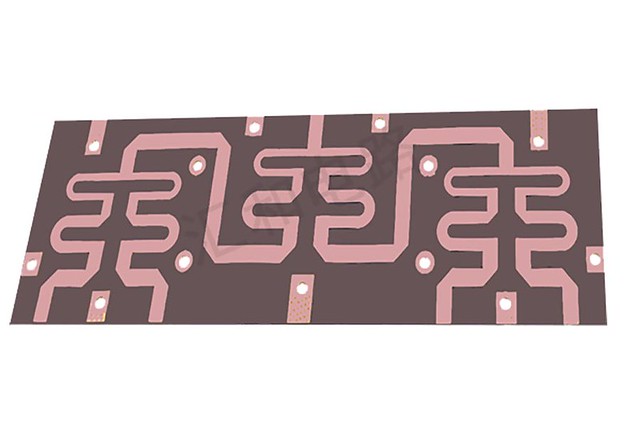

Multilayer printed circuit boards (PCBs) have become an integral part of modern electronic devices. In this article Multilayer PCB , we will explore the manufacturing process, characteristics, advantages, usage methods, tips for selecting the right multilayer PCBs and conclude with their significance in today’s technological landscape.

Manufacturing Process

Multilayered PCBs are b Ceramic PCB factory uilt by sandwiching multiple layers of copper traces between insulating layers called substrates. The whole stack is then laminated together under high pressure and temperature. This intricate process ensures efficient signal transmission while maintaining a compact design.

Characteristics

The primary characteristic of a multilayer PCB is its ability to accommodate complex electronic circuits within a small form factor. These boards provide better heat dissipation due

to their larger surface area compared to single or double-sided PCBs. Additionally, they offer reduced electromagnetic interference and improved signal integrity.

Advantages of Multilayer PCBs

1. High Density: With multiple layers available for routing connections and com Double-sided PCB ponents placement, multilayer PCBs can achieve higher density designs.

2. Enhanced Functionality: The additional layers allow designers to integrate more features into their designs without compromising on performance.

3. Space Optimization: By distributing components across various layers, these boards enable a more compact layout leading to smaller product footp Multi-layered printed circuit board rints.

4. Reliability: Multilayers help in reducing noise coupling among different circuit sections improving overall system reliability.

5. Future-Proof Solutions: As technology continues advancing at breakneck speed, using multilayers allows future upgrades without requiring complete redesign.

Usage Methods

Multilayer PCBs find applications across numerous industries such as consumer Multi-level PCB electronics, telecommunications, automotive systems,

and medical devices:

1. High-speed signal processing for data centers and network equipment.

2.The creation of sophisticated control systems in industrial automation pr Multilayer PCB manufacturer ocesses.

3.Innovative medical devices where space constraints and reliability are paramount.

4.Complex automotive electronic systems including advanced driver assistance systems (ADAS).

5.Consumer electronics, ranging from smartphones to smart appliances

.

Choosing the Right Multilayer PCB Manufacturer

When selecting a multilayer PCB manufacturer, consider the following factors:

1. Experience: Look for manufacturers with a proven track record in producing high-quality multilayer PCBs.

2. Certifications: Ensure that the manufacturer holds certifications such as ISO 9001 and IPC-6012 Class 3, indicating stringent quality control measures.

3. Design Support: A good manufacturer will offer expert design support to ensure your r Multilayer PCB manufacturer equirements are met effectively.

4. Customization Options: Check if they provide flexibility in customization based on your project specifications.

5. Timely Delivery & Cost-effectiveness: Evaluate their ability to deliver products within deadlines without compromising on quality while being cost-effective.

Conclusion

Multilayer printed circuit boards have revolutionized the world of e Multilayer PCB lectronics by providing compactness without sacrificing functionality or performance. Their manufacturing process ensures complex designs can be realized with optimized space utilization while maintaining reliability and signal integrity. By carefully selecting an experienced and reliable multilayer PCB manufacturer, you can benefit from these versatile boards across various industries and future-proof your e Multilayer PCB lectronic designs.