Multilayer PCB: Revolutionizing the Electronics Industry

Introduction:

In today’s fast-paced technological world, the demand for more compact and advanced electronic devices is growing exponentially. To meet this demand, the electronics industry relies heavily on Multilayer PCBs (Printed Circuit Boards). Ceramic PCB factory This article explores the manufacturing process, features, advantages, practical application methods, tips for selecting a suitable product, and concludes by highlighting t

he significance of Multilayer PCBs in modern technology.

Manufacturing Process:

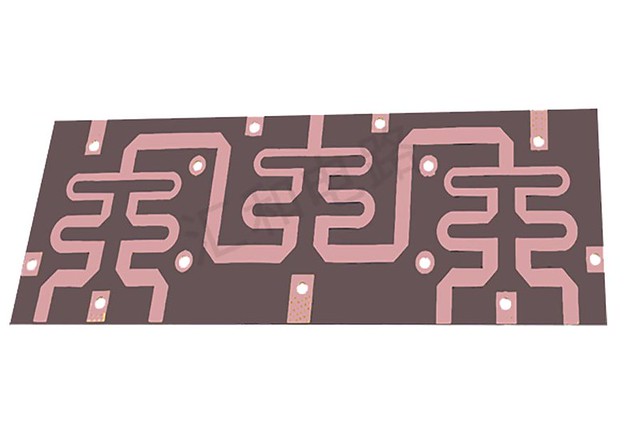

Multilayer PCBs are fabricated using multiple layers of copper foil or conductive material laminated together with insulating materials as substrates. These boards comprise numerous Multilayer PCB interconnected circuitry that facilitates communication between different components. The fabrication process involves several crucial steps such as drilling holes for inserting component leads or through-hole connectors and plating them with copper to form electrical connections.

Features:

The key feature of Multilayer Printed Circuit Boards is their a Multilayer PCB manufacturer bility to accommodate complex circuits on multiple levels. The presence of layered circuitry allows them to achieve high density integration while occupying minimal space within electronic devices. Additionally, these boards offer excellent signal transmission capabilities and exhibit low electromagnetic interference due to their improved shielding properties.

Ad Multi-layered printed circuit board vantages:

1) Compact Design: Compared to conventional single-sided or double-sided PCBs, Multilayer PCBs provide a compact design solution without compromising functionality.

2) Enhanced Functionality: By enabling multi-level connectivity through intricate wiring patterns across multiple layers, these boards facilitate higher complexity in circuits.

3) Reliable Performance: Their superior insulation properties ensure stable performance even under harsh conditions like extreme temperatures or vibrations.

4) Cost-Effective: Despite being slightly expensive dur

ing production compared to single-layered counterparts; they prove cost-effective by reducing overall device size and assembly complexity.

Practical Application Methods:

Multilayer printed circ

uit boards find extensive use in various industries where compactness and efficient performance are critical requirements. Some common applications include:

1) Telecommunications: Multilayer PCBs play a crucial role in the telecommunications industr Multilayer PCB manufacturer y, enabling efficient data transmission in mobile phones, routers, modems, and other networking devices.

2) Medical Devices: These boards are widely used in medical equipment to provide precise functionality and ensure accurate readings fo Multi-level PCB r diagnostics and treatment.

3) Computing Systems: From laptops to supercomputers, multilayer PCBs contribute to their compactness by integrating complex circuitry within a limited space while maintaining optimal performance.

Tips for Selecting a Suitable Product:

When choosing a Multilayer PCB manufacturer or supplier,

1) Consider the specific requirements of your electronic device.

2) Ensure that the supplier specializes in manufacturing Multilayer PCBs.

3) Check if they have adv Multilayer PCB anced fabrication facilities with quality control measures in place.

4) Look for certifications like ISO 9001 which demonstrate adherence to international standards.

Conclusion:

In conclusion, Multilayer Printed Circu Multilayer PCB it Boards are revolutionizing the electronics industry by providing compact design solutions without compromising efficiency. With their intricate wiring patterns across multiple layers and superior insulation properties, these boards offer enhanced functionality and reliable performance. Their application spans various industries ranging from telecommunications to healthcare. When selecting a suitable product or manufacturer, it is vital to consider specific requirements while ensuring high-quality standards. As technology continues to evolve rapidly, Mult Complex PCB ilayer PCBs will remain at the forefront of advancements driving innovation forward.