Multilayer PCB : An Overview

Introduction

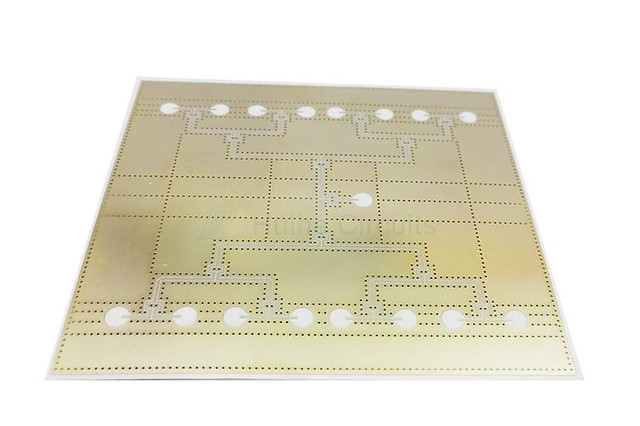

Multilayer PCBs, also known as multi-layered printed circuit boards, are an essential component in modern electronic devices. They offer increased functionality and efficiency by employing multiple la Multiple-layered PCB yers of conductive material interleaved with insulating substrates. This article aims to provide a comprehensive overview of multilayer PCBs, including their manufacturing process, features, advantages

, usage methods, tips for selecting the right product, and a concluding remark.

Manufacturing Process

The production of multilayer PCBs involves several intricate steps. The process begins with designing the schematic layout using computer-aided design (CAD) software. Next comes t Multilayer PCB manufacturer he fabrication of inner layer core materials coated with copper foil on both sides. These copper-clad cores are then aligned precisely and laminated together under high temperature and pressure to form a multi-layered stack.

Thermal bonding is employed to ensure proper adhesion between layers before drilling holes or vias through the stack for electrical connections. After that, each hole is plated with conductive material to establish interconnections between layers.

Features

Multilayer PCBs possess various featuresthat

make them highly advantageous over other types of circuit boards.

1.Double-sided PCB: Unlike single-sided boards that have traces on only one side, double-sided PCBs provide larger connectivity options due to their additional conductive laye Multilayer PCB r on the reverse side.

2.High-density interconnect (HDI) board: HDI technology enables miniaturization by incorporating finer line widths and spacings while maintaining excellent signal integrity.

3.Multiple-layered PCB: Multilayer designs allow more complex circuits within limited space without compromising performance or reliability.

Advantages

The adoption of multilayer PCs presents numerous advantages:

1.Reduced size and weight: With components distributed acr High-density interconnect (HDI) board oss various layers instead of being confined to one surface only,this type of printed circuit boardprovides compactness that saves valuable space in electronic devices.

2.Better signal integrity: Multilayer PCBs considerably reduce the chances of electromagnetic interference (EMI) since they can utilize a dedicated layer for ground and power planes. Th Ceramic PCB factory is results in improved signal quality, reduced noise, and enhanced overall performance.

3.Improved functionality: Due to their increased complexity, multilayer PCBs facilitate the integration of advanced features like impedance control and high-speed transmission capabilities.

Usage Methods

Multilayer PCBs find applications across numerous industries that rely on electrical systems. They are comm Multilayer PCB only used in:

1.Computers and laptops

2.Communication equipment

3.Medical devices

4.Automotive electro Multilayer PCB manufacturer nics

5.Consumer electronics

How to Select the Right Product?

To ensure optimal performance and reliability, consider the following factors when selecting a multilayer PCB manufacturer or ceramic PCB factory:

1.Experience: Look for a manufacturer with Multilayer PCB extensive experience in producing high-quality multilayer PCBs.

2.Capabilities: Evaluate whether they have advanced manufacturing equipment capable of meeting your specific design requirements.

3.Certifications: Check if the company holds relevant certifications such as ISO 9001 or UL certification to guarantee compliance with industry standards.

4.Customer support: A responsive customer service team is crucial for addressing any concerns during every stage, f

rom design to post-production.

Conclusion

Multilayer PCBs provide an excellent solution for complex circuits requiring higher functionality within limited space. Their versatile nature makes them ideal for various industries’ diverse needs. When choosing a reliable manufactur Double-sided PCB er or supplier, prioritize their expertise, manufacturing capabilities,and commitment to customer satisfaction. By doing so,you can obtain top-quality multilayersPCBs tailored precisely to your specifications while ensuring optimum performance in your electronic devices