Multilayer PCB: An In-Depth Analysis

Introduction:

In the world of modern electronics, printed circuit boards (PCBs) have become an integral part of nearly every electronic device. Among various types of PCBs available in the market, multilayer PCBs have gained significant popularity due to their advanced design and superior functionality. This articl Ceramic PCB factory e aims to explore the manu

facturing process, characteristics, advantages, usage methods, tips for selecting a reliable manufacturer or factory for multilayer PCBs, and concludes with valuable insights.

Manufacturing Process:

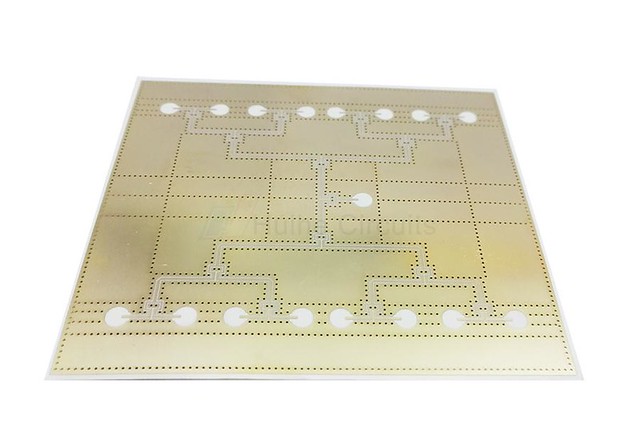

Multilayer PCBs are manufactured by sandwiching multiple layers of copper traces between insulating substrates made from materials such as fiberglass-reinforced epoxy resin known as FR4 or even ceramic materials. The intricate layering process involves etching copper layers on both sides using chemical processes and then laminating them together under high pressure and temperature Double-sided PCB conditions.

Characteristics:

Layered PCB technology provides several key advantages over single-layer or double-sided designs. By incorporating more conductive lay Multilayer PCB manufacturer ers into a smaller form factor, multilayer PCBs offer higher circuit density. They can accommodate complex interconnections among components easily while reducing signal distortion or crosstalk issues significantly. Moreover, they provide better thermal management compared to other alternatives due to the additional internal ground Multilayer PCB manufacturer planes that efficiently dissipate heat across different layers.

Advantages:

1. Enhanced Signal Performance: Multilayer construction facilitates shorter trace lengths which reduces impedance mismatch problems encountered in high-frequency applications.

2. Space Efficiency: With increased circuit density achieved through multiple internal routing layers, designers can optimize space utilization within compact devices without compromising performance.

3. Noise Reduction: Ground plane separation substantially minimiz Multilayer PCB es electromagnetic interference resulting in cleaner signal transmission.

4. Power Integrity: Dedicated power planes ensure proper distribution throughout all system components leading to improved reliability and stability.

Usage Methods:

Multilayers offer versatility across numerous applications ranging from telecommunications systems to automotive electronics and medical equipment setups. These advanced PCBs are widely used in devices where size constraints, high- Layered PCB speed signal transmission, and robust performance are critical factors. Some common applications include data storage systems, aerospace technology, industrial control systems, and consumer electronics.

How to Choose the Right Multilayer PCB:

To guarantee reliable products that meet your specific requirements, it is crucial to select a reputable multilayer PCB manufacturer or ceramic PCB factory. Consider the

following factors while making your decision:

1. Certification: Ensure that the chosen manufacturer complies with relevant industry standards such as ISO 9001 and IPC-A-600.

2. Expertise: Check for a track record of successful projects in designing and manufacturing multilayer PCBs across various sectors.

3. Quality Assurance: Look for manufact Multilayer PCB urers who prioritize quality control processes at every stage of production.

4. Technical Support: A supportive team that can assist you with design optimization, prototyping services, and troubleshooting will help ensure project success.

Conclusion:

The demand for smaller yet more powerful electronic devices necessitates the use of multilayer PCBs due to their unparalleled advantages o

ver traditional alternatives like single-layer or double-sided boards. With enhanced circuit density capabilities, improved signal integrit Multilayer PCB y characteristics often drive complex product development efforts in numerous industries today. By selecting a reliable multilayer PCB manufacturer or ceramic PCB factory while considering essential criteria like certification,c expertise,and quality assurance,you can confidently embark on your journey towards creating innovative solutions.

In conclusion,a cautious selection process coupled with tho Multi-level PCB rough consideration based on key parameters ultimately paves the way for successful integration of Multilayer printed circuit boards into state-of-the-art technological advancements