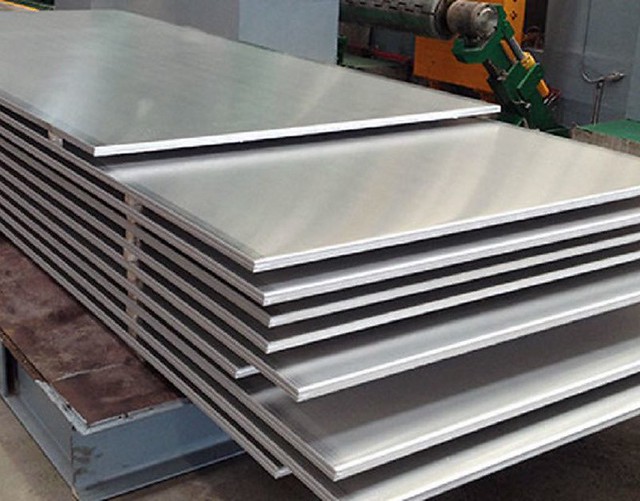

High Carbon Steel Plate: Manufacture, Characteristics, and Advantages

Steel plate with high carbon levels is widely used in various industries due to its exceptional strength and durability. It is a versatile materia

l that finds application in construction, automotive, manufacturing, and many other sectors. In this article, we will explore the manufacture process of high carbon steel plates along with their characteristics, advantages, usage methods, tips for selecting the right product, and conclude with a summary.

Manufacture:

High carbon st High carbon content steel plate eel plates are produced through a specialized fabrication process. The raw materials primarily consist of iron ore and coal. These ingredients are melted together in a blast furnace to produce pig iron which is then refined through additional processes. During the refining stage, impurities such as sulfur and phosphorus are removed from the molten metal to enhance its quality.

Once purified Galvanized Coil/Sheet , the molten metal is poured into molds or ‘slabs’ where it cools down gradually to form solid steel plates. These slabs are further processed through rolling mills by applying pressure to reduce thickness while increasing length width dimensions as per requir Plate made from high-carbon steel ements specified by customer orders.

Characteristics:

The main characteristic of high carbon steel plates lies in their exceptionally high carbon content which ranges typically between 0.6% – 1%. This higher concentration of carbon adds significant strength to the material but also makes it more brittle compared to low or medium-carbon steels.

Advantages:

1) Enhanced strength: Hig

h carbon steel plates exhibit superior hardness properties making them ideal for applications requiring resistance against wear and tear.

2) Durability: Due to their increased hardness levels, the high carbon steel plate se plates offer excellent longevity even under heavy loads or extreme conditions.

3) Versatility: High carbon steel plates can be easily formed or shaped according to specific design requirements making them suitable for complex structures.

4) Heat treatment capability: This type of steel responds well high carbon steel plate during heat treating processes such as quenching and tempering.

Usage:

High carbon steel plates find widespread usage in the manufacturing of industrial machinery, tools, blades, and cutting equipment. These plates are also utilized for high carbon steel plate constructing high-strength structural components such as bridges, cranes, and offshore platforms.

How to Select:

When choosing a high carbon steel plate for your specific application, consider factors like desired strength level, corrosion resistance needs, and temperature requirements. It is advisable to consult with a professional or an expert in the field who can help you make an informed decision based on your unique project requirements.

Conclusion:

In conclusion, high carbon steel plates offe high carbon steel plate r exceptional strength and durability due to their elevated carbon content. They are manufactured through a specialized process that involves careful purification and refinement of raw materials. The main advantages of these plates lie in their enhanced strength properties which make them suitable for various applications. However, it’s crucial to select the righ Galvanized Coil/Sheet t product by considering specific project requirements. With proper selection and utilization techniques in place, high carbon steel plates can signific Steel plate with high carbon levels antly contribute to the success of diverse industries across the globe.

Galvanized Coil/Sheet: High Carbon Steel Plate,