RFID Tag and Inventory Management

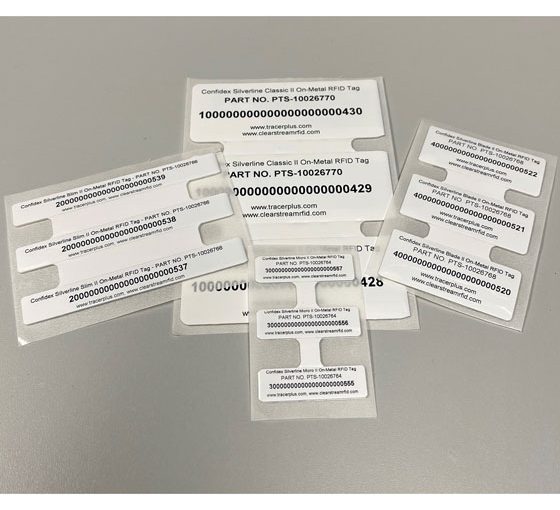

RFID is a technology that allows companies to track their assets, inventory and more. These tags contain an integrated circuit (IC) and an antenna that can be read by a reader.

RFID technology has been implemented in many different industries across the globe, and there are numerous advantages to using it. Some of these benefits include:

Inventory Management

Inventory management involves keeping track of stock items, including raw materials, work-in-process, and finished goods. It enables businesses to track and monitor the movement of goods throughout their supply chain and ensure that there is always enough stock available for customers.

RFID tags can be used to provide greater visibility and control over warehouse and distribution center inventory. They can also help to streamline operations, reduce labor costs and improve asset tracking.

Unlike barcodes, RFID tags do not require line-of-sight to scan, which is why they can be read even when items are buried under other boxes in the warehouse. This helps to improve inventory visibility and makes it easier for employees to scan and catalogue items from any location within the warehouse.

They can also be scanned quickly and easily, which means that they are much more cost-effective to use than barcode scanners. Moreover, they can be scanned in multiple locations at once, which can improve the efficiency of scanning and inventory management processes.

These benefits make RFID tags the ideal solution for inventory tracking in large warehouses. However, it is important to consider the type of inventory you wish to track before deciding whether RFID is the best option for your needs.

If you have a lot of high-value items that need to be tracked, an RFID system may be the best choice for your business. However, if you only need to track a few low-value or hard-to-scan items, barcode systems may be more appropriate for your needs.

In addition, you should consider the amount of data that an RFID tag can produce. This can be an issue if you don’t have the right servers or configurations in place to handle the influx of information that is generated by an RFID system.

Finally, it’s important to remember that RFID can be expensive to implement and maintain. In addition to the hardware and software necessary for a successful implementation, you will need to invest in employee training programs. You will also need to be sure that the RFID vendor you choose has experience implementing inventory management solutions in your industry.

Asset Tracking

RFID Tag (Radio Frequency Identification) is a technology that helps businesses track their assets, including equipment and vehicles. This process uses radio waves to transmit data from an asset’s RFID tag to a reader, which is then read by a computer program.

The information gathered can help you monitor and manage the health, safety and condition of your business’s assets. It can also provide vital information about their location and movement, which can help you respond more quickly to problems or opportunities that arise.

Asset tracking using RFID Tags can be a cost-effective way to streamline many business operations. It can also eliminate errors that would otherwise be created through manual asset management.

Regardless of the type of assets you have to track, an asset tracking system can help you improve the way you use your assets and make better decisions about their usage. It can also help you reduce the costs associated with storing, shipping and disposing of your assets.

In addition to tracking asset location and movement, RFID can be used to monitor RFID Tag their use. For example, you can track how often assets are being used or if they have failed inspections.

Another benefit of asset tracking is that it can increase efficiency by reducing the number of people necessary to do tedious tasks. Barcode scanning and RFID tagging can save employees time by automating tasks like data entry, filing and spreadsheet creation.

This makes the entire process more efficient, while ensuring data accuracy and transparency across the enterprise. It can also decrease the risk of human error by minimizing the chance of duplicate data entering the system.

The RFID tag itself has a circuit and antenna that transmits the information it contains to a reader. This can either be an active or passive tag.

Passive tags have fewer components and work in a different way than their active counterparts. They can be cheaper, but they tend to have a limited read-range.

For those looking to track higher-value or more difficult-to-reach assets, active tags are the way to go. They have a greater range and are easier to find than passive ones.

Supply Chain Management

RFID is a technology that uses radio waves to identify and track objects. It comprises a reader and a tag, which are usually made of an IC chip and an antenna. This system is a good option for businesses that want to automate inventory management, as well as those that need to improve their inventory accuracy and speed up the supply chain.

Using the power of radio waves, RFID tags can be attached to products and pallets and then read by readers. These readers beam radio signals that alert the tags to a specific Electronic Product Code (EPC), which is a unique identifier that can be attached to each item.

Once a tag is activated by the radio waves, it will transmit its EPC to a database. This data is then sent to a software interface, which can be used to analyze the information on an asset or inventory item.

The goal of supply chain management is to improve efficiency and reduce costs. Inefficient processes can cost a company money and lead to lost sales, so effective supply chain management is vital for the health of any business.

Whether a company is importing raw materials from overseas, sending products to stores, or distributing them through distribution centers, it is crucial that the process be managed smoothly and efficiently. The best way to achieve this is by using technology to streamline the process.

Logistics assets like trucks, containers, and forklifts can be tagged with RFID tags so that warehouse employees can know where the equipment is at all times. This will make it easier for them to transport products to customers and help them avoid mistakes such as mishandling.

A RFID system can also be integrated with a warehouse management system (WMS) to ensure that each product gets scanned as it enters or exits the warehouse. This data can then be used to track products, including their location within a warehouse or distribution center.

Real-time tracking of shipments is critical for keeping supply chains running smoothly, especially if a shipment faces unexpected delays, such as bad weather or road conditions. This data can be used to develop at-the-moment contingency plans to ensure that shipments don’t get stuck. In addition, it can be used to ensure that a company’s inventory is in compliance with customer demands and safety standards.

Security

RFID tags are a popular solution for asset tracking and inventory management. But, like all wireless technologies, they can be vulnerable to security attacks. These threats include skimming, eavesdropping, and cloning.

One way to protect your data is to use encryption. Encryption helps you create a system that makes it difficult for an RFID Tag intruder to decipher the contents of your RFID chip.

Another option is to use a lock password, which requires the tag to send a unique code before it shares its information. The code can have up to 4 million possible combinations, making it difficult for hackers to crack the password and access your RFID chips’ data.

This method is perfect for systems that have limited computational capabilities or cannot run a complex encryption algorithm. However, it can also be difficult to manage passwords for all your tags in a large organization.

If your RFID chips are sensitive, you can also consider using challenge response authentication. This system requires both the reader and the tag to communicate over a cryptographic network. The key that is used to decipher the data between the two devices never leaves the reader or the tag’s memory, which prevents unauthorized parties from stealing the data through skimming and eavesdropping.

In addition, you can also choose to install a kill code that will make the tag unresponsive to anyone who wants to access its information. This is a great option if your company has been compromised and you want to wipe out any stolen RFID chip data before it can be used for malicious purposes.

Finally, you can choose to use a shield that surrounds the RFID chip. This shield protects the chip from physical damage and prevents a bad actor from scanning the tag.

All of these features help you protect your business and assets from theft and sabotage. They also help you protect your employees from becoming victims of identity theft and fraud. In addition, they help you improve productivity and efficiency by ensuring that every tagged asset is accurately tracked and associated with its correct information.