What Is a Server PCB?

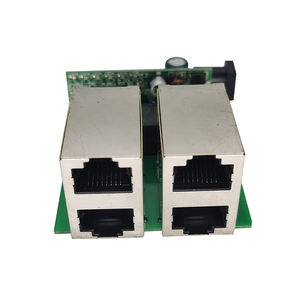

A Server PCB is a printed circuit board that is used in computer servers. It includes a central processing unit, memory, network interfaces, and power supply.

The PCB is the key component of a computer system. It is an insulating, copper-coated board that connects all of the electronics in a computer to each other and the external devices connected to it.

Material

The material used for a PCB can have a big impact on the performance and appearance of a product. There are many types of materials available and the one you choose depends on your application, results needed and environmental constraints.

The base material of a PCB can be rigid or flexible, depending on the design. Manufacturers often use fiberglass, such as FR-4, for rigid sections and high-temperature flexible plastics (e.g., polyimide or PEEK) for flexible sections.

Another common material is aluminum backed PCB, which has an aluminum substrate instead of fiberglass. This material has a higher thermal conductivity than fiberglass and can dissipate heat more efficiently, which is why it’s used in power supply controllers and AC/DC converters.

There are several layers that make up a PCB, including the base material, conductive pathways, solder mask and silk screen. Each layer uses a different material.

1. FR-4: This material is the most common. It is a woven glass-reinforced epoxy laminate sheet with a flame-resistant resin binder. It’s made by melting raw glass and then weaving it into a variety of fiber yarns, which are then coated with a coupling agent and a resin that improves its adhesion.

2. Prepreg: This material is similar to FR4 but it has an adhesive layer that provides strength. It’s a very popular choice for PCB boards because it has good electrical fire safety and dimensional stability.

3. PTFE: This material is a very strong and lightweight material that is also flame resistant. It’s preferred in applications where tolerances Server PCB are tight, and it doesn’t expand much when exposed to high temperatures.

4. FR4: This is the most popular material for most printed circuit boards, although there are other options that can be more appropriate for specific applications.

5. Aluminum backed: This is an alternative to FR-4 that has an aluminum substrate instead of fiberglass. It has a much higher thermal conductivity than fiberglass and can dissipate the heat of many power sources more efficiently.

There are several other materials that can be used in PCB manufacturing, but the most common ones include FR-4, PTFE, and aluminum backed. Each has its own unique characteristics and benefits.

Technology

Printed circuit boards (PCBs) are used to connect components to one another for electronic devices. These boards are manufactured using materials like copper and plastic. There are many different types of PCBs that can be used for different applications. Some of these include rigid and flexible PCBs.

Rigid PCBs are used in products that need to be extremely sturdy, such as laptop and desktop computers. They are also used in industrial machines.

These PCBs are usually made of a rigid material in order to prevent them from twisting and bending. This helps ensure that the circuit will be functional for a long period of time.

The technology that is used to create these PCBs depends on the type of component that is being placed on the board. Some of the most common methods of adding components to a board include through-hole and surface mount technology.

Through-Hole Mount – In this technology, leads are mounted into holes that are drilled in the board. This method is often used in single-layer PCBs, but it can be difficult for more complex designs.

Multilayer PCB – These PCBs are typically designed with three or more layers of conductive copper foils and an insulating material. They are used in a wide variety of applications, including data storage and communication systems.

Their durability and low weight properties make them an ideal choice for applications that require high-speed circuits, such as in military equipment. They are also a popular choice for home appliances and science and research applications, where their space-saving properties help keep them light while still maintaining exceptional functionality.

The technology that is used to create these PCBs can be customized to the specifications of each user. For example, if the user wants to use a specific material for the PCB, they can request it. This can save them money in the long run by avoiding unnecessary costs.

Design

Server PCBs are used in a wide variety of products, including routers, switches, computers, network devices, industrial equipment and more. They are often fabricated with multiple layers, which helps them withstand harsh environments and keep their components and circuits safe from damage.

They can also be adapted for use in the manufacture of many types of electronic devices, such as mobile phones, cameras, and TVs. They are especially useful for small-scale devices that don’t need the space and cost of traditional single-sided or double-sided boards.

One of the main benefits of a multilayer PCB is its high density, which allows it to accommodate more components than would be possible on a single-sided board. This allows designers to produce small-scale and lightweight products that still have the capability to perform efficiently.

Another benefit of a multilayer PCB is that it can be manufactured with multiple thermal vias, which help dissipate heat and increase the reliability of the device. This is particularly important in devices that can experience rapid power changes, like servers and other network appliances.

Choosing the right materials for a multilayer PCB can be crucial to achieving the performance and reliability desired by engineers. A design that combines proper layout with the correct materials can significantly reduce the number of failures.

For example, a poor design can cause output voltage regulation problems, erratic soft-start operation, and device operational issues. The best way to avoid these problems is by following a good power design guideline, which includes appropriate separation and placement of power and ground planes on the PCB.

The best way to accomplish this is by ensuring that each of Server PCB the power supplies is separate from any other supply on the board and by routing all of the small-signal components on one side of the PCB to improve routability. This ensures that there is no potential for a faulty circuit to create an unexpected power loop.

Allegro PCB Symphony offers a team design option that shortens the biggest portion of the board layout process by allowing multiple routing engineers to work on a shared canvas. This ad-hoc mode eliminates the setup requirements that are associated with partitioned projects, enabling teams to work together on the same project in a secure environment.

Applications

PCBs are used for a variety of applications in the electronics industry, including computers, phones and vehicles. They are also a staple component of most industrial machinery.

For example, computer circuits are often printed onto PCBs for efficient and consistent operation. This saves money on the time and energy it takes to manufacture and test equipment.

Another use for Server PCBs is in the telecom industry, where they are a critical component of high-speed data networks and transmission technology. They are able to handle massive amounts of power and deliver high-speed signals at a high level of reliability.

As the world continues to become more technologically advanced, the need for multilayer PCBs has increased. These boards offer optimized benefits for complex needs, which is why they are increasingly used in many different kinds of electronics.

These boards are also commonly used for telecommunication devices, such as satellite systems and GPS technology. They are especially useful in high-speed applications that require durability and functionality while being lightweight and compact.

The telecommunication industry is constantly changing, which means that the technology required to support it will also need to evolve. As a result, the PCBs that are used in the industry will need to be more powerful and reliable than ever before.

This is because of the increasing amount of data that is generated and transmitted around the world. As a result, the needs for Server PCBs will continue to grow as technology improves and more people need access to it.