What Is a Wiring Harness?

A wiring harness is an assembly of electrical cables. It is used to connect and transmit signals and electrical power from one end to the other. Depending on the type of wires and the purpose of the cable, the harness can be called a Wire Harness, Wire Assembly, or Cable Harness.

Automotive

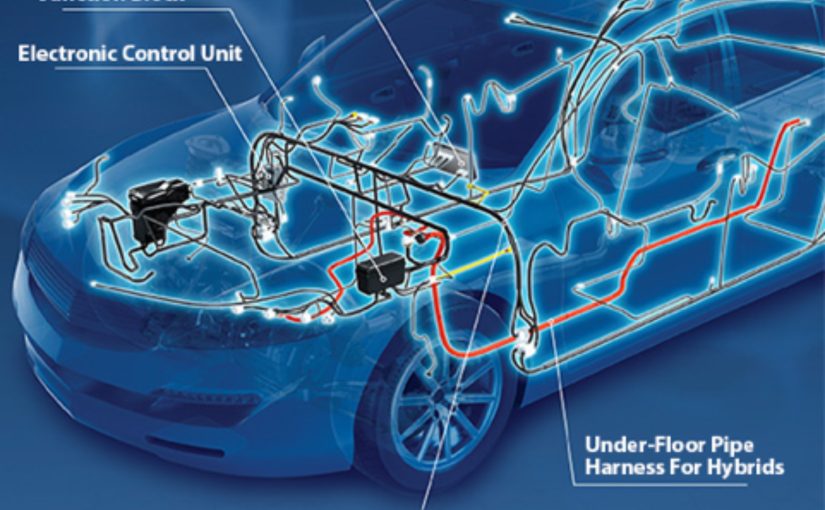

Automotive wiring harness is a system that establishes connections between various vehicle components. It includes sensors, actuators, batteries, electrical appliances, etc. The system also transmits data between various electrical components in a vehicle.

Automotive wiring harness is becoming increasingly important for a number of reasons. One of the major ones is the increased adoption of autonomous vehicles. These vehicles are using ML and other technology to provide advanced features. Another reason is the rising demand for passenger cars.

There are a variety of electronic devices in a car, including power, communication, and infotainment. They need a robust wiring harness to connect them. This is especially important because the wires in a vehicle can wear out or be damaged, which can cause system failure at a larger scale.

Increasing investments by key players in research and development are expected to drive the automotive wiring harness market. Start-ups are also trying to establish their own niche in the market. Some of these start-ups are looking to replace traditional wiring harnesses.

During the forecast period, Asia Pacific is estimated to account for the largest share of the global automotive wiring harness market. This is due to the growing demand for electric and battery-powered vehicles. In addition, the rising disposable income of Chinese consumers is anticipated to fuel the growth of the regional market.

China is the world’s leading producer of both ICE and electric vehicles. It has over 30% of the global production capacity.

Aerospace

The Aerospace wiring harness is a system that interconnects wires within an aircraft. This assembly is composed of hundreds of components that are designed to withstand extreme operating conditions. It provides service to the control system, switch, and trunk lines.

Aircraft wiring harnesses can be used for military, commercial, and civil applications. They can be manufactured for high altitude environments, inter-shelter communications, and high voltage applications.

Aircraft wiring harnesses are made to comply with IPC/WHMA-A620 Class III, and MIL-STD-454 specs. Custom manufacturers offer low and medium volume production as well as prototypes. Currently, the aerospace wiring harness market holds the largest share in North America, Europe, and Asia-Pacific regions.

Increasing use of electrification is one of the major drivers for the aerospace wiring harness market. The increasing demand for new commercial aircraft is another driving force.

Among the regions, the Asia-Pacific region is expected to show the highest growth over the next few years. The increase in air travel is fueled by disposable incomes, as well as changing lifestyles. Moreover, the rapid urbanization of APAC is a key factor driving the Aerospace Wiring Harness market.

One of the key trends in the Aerospace Wiring Harness market is the increased use of regional aircraft. These aircraft connect distant points without direct flights. Consequently, there is a need for compact wiring.

The global aerospace wiring Led Driving Light Bar harness market is expected to witness the highest growth rate during the forecast period. There are several opportunities for aerospace wire harness players to expand their business.

Manufacturing

Manufacturing wiring harnesses can be a complicated process. It involves a blend of fully automated and semi-automated processes.

Despite the complex nature of the process, there are several things that you can do to increase the speed and efficiency of your production. These include incorporating paperless manufacturing. The result is less time spent on manual data transfer, which reduces costs. This can help you meet stringent customer requirements while increasing your profit margins.

You can also improve your work instruction system. This will allow anyone to carry out their task quickly. For example, you could use an automatic setup for the terminal crimping machine. Similarly, you could use a wire clamp position designating jig.

Finally, you can automate your data transfer processes. For example, you could use a bar code to read the ID seal on the end of each wire. By doing this, you can ensure that you get the correct data when processing.

Ultimately, you can use automation to produce documentation for assemblers on the shop floor. This will enable you to minimize production errors and reduce your overhead costs.

In addition, you can use advanced modeling software to see how your system will perform. This will save you time and money during the prototyping phase.

While it is important to use the most efficient production methods, you can still increase your productivity by outsourcing wire harness manufacturing. Doing so will not only help you lower your costs, but also guarantee that your inventory will never run out.

Public utilities

A public utility is a public utility, and the wires nay the trees that aren’t the tree trunks if you ask me. The big three are power, gas and water. Among the three, electricity is the juiciest. There are several noteworthy public utility companies in Illinois, albeit, it isn’t easy to keep them in check. In this regard, the state’s Department of Consumer Affairs has some interesting initiatives. One such program is the “Ask the utility guy” program. For the uninitiated, this may be the best place to start. If you’re not looking to be a stooge, it might be best to keep your cool. While the office may be a bit more laid back than your usual cubicle mate, it’s hard not to take note of their exemplary customer service, which is the reason they’re able to maintain the highest customer retention rates in the industry.

Terminals

Wire harness terminals are important components of a wiring harness. They act as a conductive element that allows electrical signals to pass between corresponding components in a wiring harness. The terminals can vary in shape, size, and insulation. In order to select the right type of terminals for a particular application, it is important to understand what each one does.

Spade/fork terminals are fork shaped terminals that are designed for harness applications with a tight space requirement. These terminals are typically used to extend wires and are available in various sizes, gauges, and insulation levels.

Quick-disconnect terminals, also known as bullet connectors, are commonly used in automotive and industrial applications. These terminals are insulated to provide quick connect and disconnect for two wires.

Wire ferrule terminals are also a type of quick-disconnect terminals. They are designed to protect the wire opening from dirt and stray cables. Depending on the wiring harness design, it is important to choose the correct type of terminals.

Flag Terminals, also called flag connectors, are great for tight spaces. This type of terminal provides a convenient connection and offers a 90 degree Led Driving Light Bar bend. It is insulated and can be soldered or crimped.

Butt Terminals are a common type of terminal that connects single wires and multiple wires. They are easy to attach and remove from screws. Moreover, they offer abrasion and moisture protection.

Wire terminals can be divided into sheet and cylindrical series. Sheet series is made of H65Y material, while the cylindrical series is composed of Qsn6.5-0.1 material.

Test for continuity and electricity flow

You can use a multimeter to test for continuity and electricity flow on a wiring harness. But, before you start testing your circuit, you should first know what the multimeter is, and what it measures.

First, you should understand the multimeter’s resistance settings. The resistance setting tells you how much resistance your circuit has to resist the flow of electric current. This measurement is essential for checking the insulation of motor terminals, and checking thermistors.

Next, you should be able to tell whether the pathway you’re measuring is complete or open. An interruption in the path of current may be caused by a broken or damaged component.

A multimeter with a built-in continuity mode can help you determine if your electrical connection is complete or open. Most multimeters will emit an audible response when they detect a full path.

Another good way to determine whether your wiring harness is complete or open is to test it using an Ohmmeter. Using an ohmmeter to measure resistance can be especially helpful for testing circuits that have many wires and components.

A multimeter’s most powerful feature is its ability to measure resistance. If the resistance is low, the pathway is open. However, you should be careful not to apply too much voltage to the circuit. Too much voltage can damage your components.

There are several types of continuity testers available. They usually have two leads that touch the opposite ends of an electrical pathway. These leads are often alligator clips attached to long insulated wire leads.