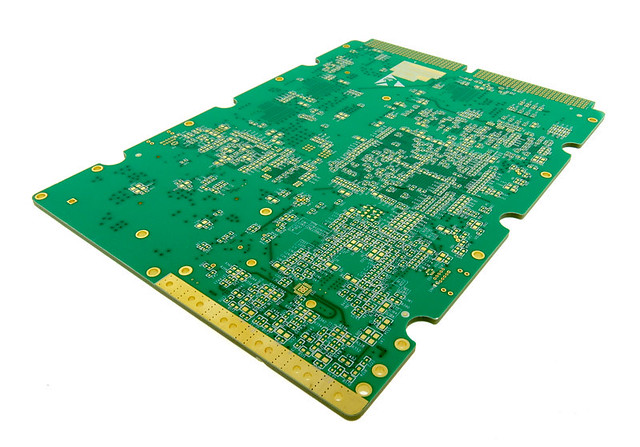

High Frequency PCB: A Game Changer in Advanced Electronics

Introduction

High Frequency PCBs (HFPCBs) have revolutionized the manufacturing and functionality of advanced electronics. In this article, we will explore the

features, advantages, usage methods, and selection criteria for HFPCBs. We will also delve into other key types of PCBs such as HDI-PCB, Microwave PCB, EMI/EMC PCB before drawing a conclusion on why HFPCBs are becoming increasingly popular.

Manufacturing Techniques for High Frequency PCBs

To cater to the demand for high-performance electronic devices operating at gigahertz frequencies, specialized manufacturing techniques have been developed. These involve precise control over materials used and Microwave PCB fabrication processes employed.

One common method is using PTFE (Polytetrafluoroethylene) substrates due to their excellent dielectric properties which result in low electrical loss and minimal signal distortion. Another tec Single Sided PCB hnique is employing hybrid constructions that combine specific materials like ceramic-filled PTFE or blending fiberglass with epoxy resins.

Characteristics of High Frequency PCBs

HFPCBs possess several characteristics that make them indispensable in modern electronics:

1. Low Signal Loss: Th Flexible PCB e design intricacies reduce interference from external factors while ensuring minimal energy dissipation during signal propagation.

2. Controlled Impedance: Precisely engineered transmission lines provide optimal impedance matching between source components and receivers.

3. Minimal Crosstalk: Advanced substrate materials minimize undesired electromagnetic coupling between traces or conductors.

4. Effective Heat Dissipation: Customized heat sink designs enable efficient thermal management even at high-frequency operations.

Advantages of High Frequency PCBs

Incorporating HFPCBs yield numerous benefits:

1.Excellent Signal Integrity: High-quality transmission lin High Frequency PCB es ensure reliable signal transfer without deterioration during high-speed data transmission.

2.Improved Performance & Reliability: Reduced noise levels enhance device performance while improved thermal management increases operational stability.

3.Compact Design Realization: HFPCBs enable miniaturization, making them suitable for portable electronic devices where size is a High Frequency PCB constraint.

4.Enhanced Frequency Response: High-frequency operations are achieved precisely and consistently with minimal signal distortion.

Usage Methods of High Frequency PCBs

HFPCBs are widely used in various applications:

1.Communications Industry: Modern wireless communication syst High Frequency PCB ems rely heavily on HFPCBs for effective data transfer.

2.Radar Systems: The high frequency enables accurate and quick data acquisition in radar-based surveillance or navigational systems.

3.Satellite Communication: Satellite transceivers employ HFPCBs to facilitate stable and reliable connections across vast distances.

4.Aerospace & Defense Electronics: Many advanced aerospace technologies leverage the superior performance of HFPCBs.

How to Select the Right High Frequency PCB Supplier

When sourcing your next project’s high-frequency PCB, consider the following EMI/EMC PCB (Electromagnetic Interference/Electromagnetic Compatibility PCB) factors:

1.PCB Manufacturer Expertise: Look for suppliers specializing in high frequency design Smart door lock supplier and fabrication expertise backed by quality certifications such as ISO 9001 or ITAR compliance.

2.Material Selection Capability: Ensure that your chosen supplier can provide a wide range of substrate materials including PTFE laminates, ceramic-filled composites, or fiberglass-reinforced epoxy resins based on specific requirements.

3.Manufacturing Equipment & Facilities Quality Standardization : It is crucial that suppliers have state-of-the-art manufacturing facilities with advanced equipment capable of ensuring precise tolerance control during fabrication processes.

Conclusion

High Frequency PCBs are at the forefront of technological advancements within the electronics industry. Their unique characteristics such as

low signal loss, controlled impedance, minimal crosstalk, and excellent heat dissipation make them essential components in modern electronics. When selecting an HFPCB supplier for your next project, prioritize their expertise, material selection capability, and manufacturing standards. By harnessing these attributes effectively through a trusted supplier partnership ensures optimal perfo HDI-PCB (High Density Interconnect-Printed Circuit Board) rmance and reliability for your electronic devices.