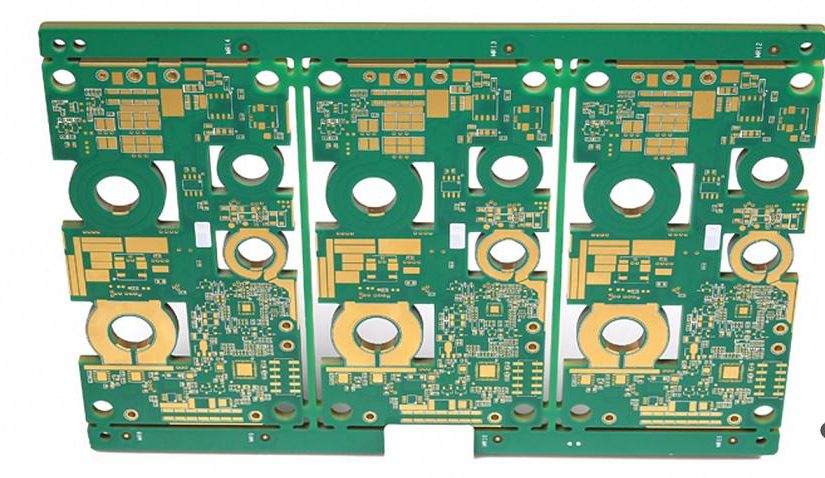

Heavy Copper PCB and Its Uses

Printed circuit boards are widely used in many industries, such as telecommunication, automotive, medical, military and renewable energy. They are highly efficient and have the ability to withstand high temperatures, fast speeds and other critical design requirements.

Heavy copper PCBs are an increasingly popular option in the industry, utilizing 3 or more ounces of finished copper in the inner and outer layers. These thicker copper PCBs have several advantages over standard Printed Circuit Boards, including cost-effectiveness and high conductivity.

Cost-effectiveness

A heavy copper pcb is one of the most cost-effective options for high-power circuits. These boards have thicker traces than standard PCBs so that they can produce the higher amperage of electrical current needed to power devices, including military and industrial equipment, solar panels and welding systems.

These boards are also useful for medical applications that require large currents to operate, as well as in power supplies. They are able to handle the power requirements without compromising the efficiency of the circuits or the safety of the device.

As a result, these boards are used by a variety of industries, including military/defense and automotive. These industries are required to design products that can withstand the heat of today’s complex electronics.

To make a heavy copper PCB, specialized plating and etching processes are used. These processes add copper thickness to via sidewalls and plated holes, making them stronger and less likely to weaken over time.

The added copper thickness also allows for the use of exotic materials to their maximum potential without sacrificing the integrity of the circuit. In addition, these boards are more resistant to circuit failure and reduce product size by incorporating multiple copper weights on a single layer of circuitry.

Besides the increased conductivity, heavy copper pcbs are also more durable and have better thermal management properties than conventional circuits. The ability to distribute heat efficiently and dissipate it in the environment can prevent overheating of vital components.

This also reduces the need for cooling, which can help to extend the life of your electronics. It can also help to minimize the number of manufacturing steps and cut costs by avoiding production mistakes that are more expensive to fix after the fact.

When choosing a heavy copper PCB, consider the following factors:

Size and spacing: Effective utilization of materials is closely tied to the size and spacing of your board. If you need more space on your PCB, you will have to use more prepreg in processing steps to fill the gaps between the copper foils. You also may need to add more reflow stations or other tools to process your board effectively.

High conductivity

In the electronic world, PCBs are essential components. They are used in different gadgets from toys to complex devices such as military equipment. However, they are mainly used in low-power and low-voltage devices to ensure proper operation of the device.

Heavy copper pcb is a type of circuit board that uses 4 or more Oz of copper on each layer to provide high thermal endurance and current carrying capacity. This type heavy copper pcb of PCB is commonly found in power electronics devices and power supply systems.

The primary benefit of a heavy copper pcb is its ability to survive frequent exposure to excessive current, elevated temperatures and recurring thermal cycling which can destroy regular circuit boards in seconds. This capability makes it an ideal choice for applications in rough conditions such as military/defence industry products, power adapters/alternators, thermal regulators and many more.

Another advantage of a heavy copper pcb are its plated through holes, which provide good thermal distribution and improve mechanical strength. These vias disperse the heat produced by a board much faster than the fan cooling system can.

Additionally, a heavy copper pcb offers better thermal conductivity and lowers the failure rate of temperature-sensitive components. This helps to increase reliability and reduces production costs.

When designing a heavy copper pcb, the designer must first gauge the amount of current that needs to be carried and based on this, they select the right copper thickness and width. Next, they calculate the maximum temperature rise the board can withstand and design the circuit accordingly.

In addition to this, the designer must take into account the substrate material and its resistance to conductive flow and its temperature coefficient. They must also consider the mechanical stress delivered to the plated through holes and the surface finish of the copper traces.

These considerations are a must during the design phase because they influence the amount of heat the PCB will generate, as well as its reliability and longevity. A trace width calculator can help determine these factors and help the designer create a reliable circuit board.

Thermal management

One of the biggest challenges in designing a PCB is how to keep it cool enough so that components don’t overheat and shorten their life. This can be especially problematic in applications that involve space, aviation, or military use.

Heat is the enemy of designers, but there are ways to prevent it from affecting their work. In most cases, thermal management begins with the proper design of the board and its layout. In addition, it also involves using certain manufacturing techniques to reduce the amount of heat and improve its dispersion.

Heavy copper pcbs are used in a variety of applications, including power systems for aircraft and vehicles, computer processors, wearable electronics and more. The technology has been around for a while, but it’s now becoming more widespread in mainstream electronics production as engineers develop systems that can withstand varying conditions.

As with any PCB, the thickness of the copper traces will affect how much heat they can absorb. Hence, it is essential that the tracks be designed with a large distance between them to limit thermal transfer. This will allow the heat to flow away from the copper traces without overheating.

Another important consideration is the width of the copper traces. This will determine how well they carry the current and how well they dissipate it. The width of the copper traces should be kept as small as possible, but also consistent with the rest of the board.

There are many factors that impact the thickness of the copper traces on a board, including the thickness of the layer and the track layout. The width of the copper traces can be minimized by using thinner materials, but this will limit their performance.

When a PCB carries high current, the copper traces will generate heat. This heat can be dissipated in a variety of ways, but it is most commonly dissipated by convection.

The design of a PCB should take this into account to ensure that the board can handle high currents and that it won’t become overheated. This can be done by designing the boards with large cross-sections for high current loads and by implementing thermal pads, blind vias, and other means of conducting the heat.

Reliability

When you want to design a PCB, it is essential to consider the reliability of the product. If you don’t, you might end up with a board that cannot work properly and can be very expensive to repair or replace.

Heavy copper pcb is an excellent choice because it is heavy copper pcb extremely durable and can withstand a lot of stress. It also provides a solid connection between components and ensures that the circuit is functioning properly.

These types of boards are used in electronics, computers, and appliances. They are also great for handling heat. However, you need to make sure that you use the best ones.

One of the main reasons why a heavy copper PCB is so reliable is because it can handle high current. This allows the board to last longer and perform better.

Another reason why these kinds of boards are so reliable is because they have thicker plating in the through-hole circuits and an appropriate substrate combined with the copper weight. This combination can transform a flimsy board into a stable wiring platform that can support multiple operations.

Aside from being durable, heavy copper PCBs are able to resist frequent exposure to excessive current and elevated temperatures. These conditions can damage regular circuit boards in seconds, so they’re a must-have for applications that are exposed to rough situations.

The most common industries that use these kinds of boards are military/defense, solar panel and welding equipment manufacturers, and industrial controls. They are also used in power adapters and other equipment that requires heavy current.

Because they can handle high current, these boards are able to dissipate heat efficiently. This helps to prevent overheating and damage to the electronics.

It is important to remember that the thickness of a copper layer in the circuit board determines how much heat it can absorb. This is because the amount of current that a PCB carries is proportional to its thickness.

This makes heavy copper PCBs a good choice for any electronic device that needs to endure frequent exposure to a lot of heat. This is especially true when you need to use it for a long time.