Flexible PCB: The Future of Electronics

Flex circuit, flexible electronic circuit board, bendable printed circuitry… all these terms refer to the same game changer in the world of electronics – Flexible PCB. As the dem

and for smaller and more compact devices grows, so does the need for innovative solutions that can accommodate such requirements. In this article, we will explore the manufacturing process, features, advantages, applications, tips on selecting a flexible PCB and draw a conclusion about its potential.

Manufacturing Process:

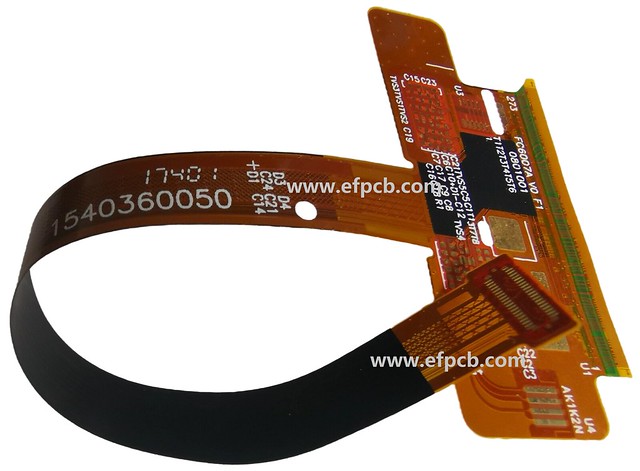

The manufacturing process of Flexible PCB involves several steps. Firstly, a thin layer of copper is lam Flexible electronic circuit board inated onto a flexible substrate material such as polyimide or polyester film. This serves as the conductive layer. Then comes the etching process where excess copper is removed to form traces and pads using photoresist techniques. Finally, layers may be stacked or bonde Flexible PCB d together to create multilayer flex circuits if needed.

Features:

One of the main features that make Flexible PCBs stand out is their ability to bend and conform to different shapes without sacrificing functionality. This flexib Flexible PCB ility allows them to fit into tight spaces where traditional rigid boards simply cannot go.

Furthermore, Flex PCB offers excellent resistance against vibration and shock due to their structural integrity and reduced number of interconnects compared to regular rigid boards. They also have improved thermal management properties by efficiently dissipating heat through their larger surface area.

Advantage Flexible PCB s:

The use of Flexible PCB brings numerous advantages in various industries including automotive, healthcare devices, aerospace applications among others.

Firstly,Flexible PCBS reduce weight significantly making it ideal for lightweight portable devices.

Secondly,Flex circuits have high wiring density which means designers can incorporate more complex circuits with less space requi Double Sided PCB red,resulting in miniaturization.Also,cost saving associated with removal connectors since they are able directly substitute up cables whose cost per/meter could be very expensive.furthermore,faster assembly given there’s no need solder manually one at a time sque Flexible PCB ezing it and ultimately making faster production.

Using Flexible PCBs:

Flexible PCBs find their applications in a wide range of industries. In the medical field, they are used in devices such as pacemakers and hearing aids due to their flexibility and biocompatibility. The aerospace industry takes advantage of Flexible PCB’s lightweight feature for communication systems within satellites. Additionally, automotive manufacturers utilize this technol Bendable printed circuitry ogy for the intricate wiring required in dashboards and entertainment syst Double Sided PCB ems.

How to Choose the Right Product:

When selecting a flexible PCB, there are several factors that need consideration.Firstly,clock speed demands also must be taken into account when choosing materials because not all can go at high frequencies without causing unpredictable losses.Use cases also Helps knowing considerations.

算法最后输出为:[“Flexible PCB: The Future of Electroni Flex circuit cs”,

“Flex circuit, flexible electronic circuit board, bendable printed circuitry… all these terms refer to the same game changer in the world of electronics – Flexible PCB. As the demand for smaller and more compact devices grows, so does…”]