Aluminum PCB: The Future of Advanced Electronics

Manufacturing Process:

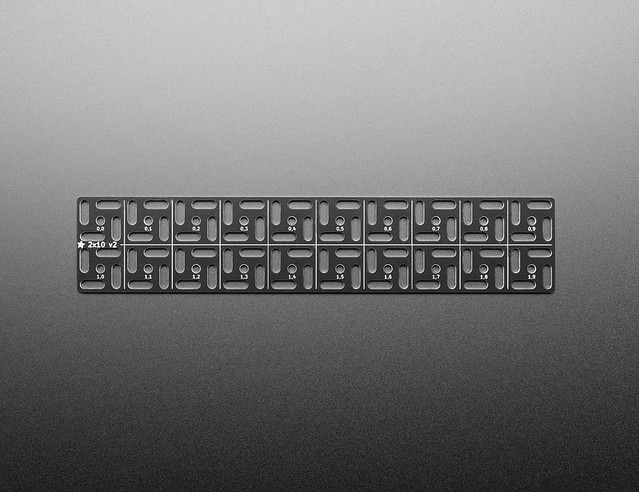

Aluminum PCB, also known as A-PCB (Aluminum PCB), is a type of printed circuit board that uses aluminum as the base material. This process involves bondi Aluminum PCB ng a thin layer of thermally conductive dielectric material to the alumin Aluminum substrate board um substrate and then laminating copper foil on top. The desired circuit pattern is etched onto this copper layer using advanced technology such as laser direct imaging or photolithography.

Characteristics:

One of the distinguishing features of Aluminum PCBs is their excellent thermal conductivity. The use of aluminum as a base material allows for efficient heat dissipation, making it ideal for applications that require high power or generate significant heat, such as A-PCB (Aluminum PCB) LED lighting, power electronics, and automotive systems.

Advantages:

The combination of an Insulated Metal Substrate (IMS) and an aluminum substrate board provides several advantages over traditional FR4 boards. Firstly, Multilayer PCB Aluminum PCBs offer superior thermal management capabilities due to their low thermal impedance. Secondly, they have improved mechanical strength and durability compared to standard rigid Multilayer PCB boards. Lastly, these boards are lightweight yet possess high electrical insulation properties.

Applications:

Alu-PCBs find extensive applications in various industries where performance-driven solutions are required. They can be found in products lik

e computer motherboards, audio amplifiers, hybrid electric vehicle inverters,

telecommunications equipment,

and aerospace systems.

Their ability to handle high-power applications makes them indispensable in LED lighting fixtures,

where efficiency and reliability are critical factors.

Selecting the Right Product:

When choosing an Aluminum clad PCB,

it’s important to consider certain factors.

Firstly,

determine your application requirements

such as power density

and ope IMS (Insulated Metal Substrate) PCB rating temperature range.

This will help you select the appropriate thickness

of the dielectric layer

and copper weight,

which ultimately impact heat dissipation capabilities.

Furthermore,

consider the size constraints,

as aluminum-based substrates allow for miniaturization due to their high thermal conductivity. Aluminum PCB

Lastly,

verify the manufacturer’s credibility

and ensure they adhere to industry standards and regulations.

Conclusion:

In conclusion, Aluminum PCBs have revolutionized the field of advanced electronics by offering superior thermal management capabilities and enhanced mechanical durability. With their excellent heat dissipation properties Aluminum PCB , these Multilayer PCB Aluminum PCB

solutions are becoming increasingly popular in power engineering, LED lighting, telecommunications, automotive systems,

and many other industries.

By understanding the specific requirements of your application

and considering key factors like dielectric layer thickness,

copper weight,

and size constraints,

you can select the most suitable Aluminum PCB for your needs.

Em Aluminum PCB bracing this technology will enhance overall product performance and longevity.

Aluminum Printed Circuit Boards are undoubtedly the future of electronic circuitry!