Aluminum PCB: A Comprehensive Overview

Manufacturing Process:

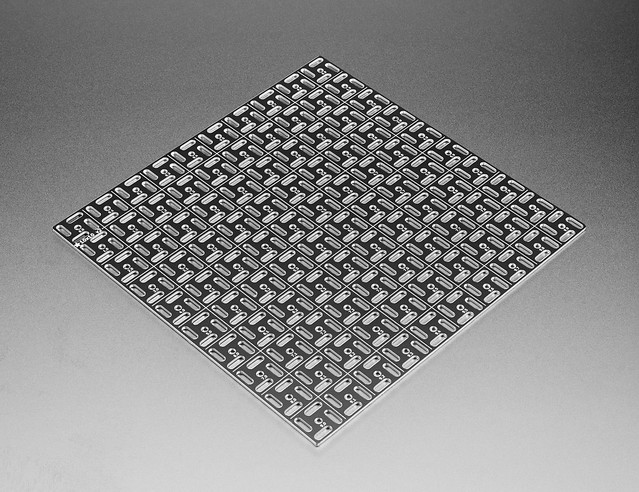

Aluminum PCBs, also known as Aluminum substrate boards or IMS (Insulated Metal Substrate) PCBs, are manufactured using a specialized process. The base material is a thin laye Aluminum substrate board r of aluminum that acts as both the structural support and electrical conductor for the circuit traces. To create the circuitry, a layer of copper is laminated onto the aluminum substrate through a combination of heat and pressure. This copper layer is then chemically etched to form the desired circuit pattern.

Features:

One notable feature of Aluminum PCBs is their excellent thermal conductivity. The aluminum substrate efficiently dissipates Multilayer PCB heat generated by high-power components, making them ideal for applications requiring effective heat management. Additionally, Aluminum PCBs possess good mechanical strength due to their robust construction.

Advantages:

The use of Aluminum PCBs offers several advantages in electronic designs. Firstly, they provide impr Aluminum PCB oved heat dissipation compared to traditional FR4 boards, ensuring better reliability and longevity of electronic devices operating under high-temperature conditions. Moreover, their lightweight nature allows for compact and portable device designs without compromising performance. Furthermore, Aluminum PCBs exhibit low thermal expansion coefficients when subjected to temperature variations.

Applications:

Blending

innovations in technology with creative design ideas has resulted in tremendous advancements across numerous industry verticals – be it automotive engineerin Aluminum PCB g or consumer electronics.

Usage:

Given its unique properties such as outstanding thermal conductivity which make it especially well-suited for power LED lighting products.

How to Select an Aluminum PCB:

When selecting an Aluminum PCB provider or manufacturer,

Conclusion:

In conclusion,

Overall,

To summarize,

Title: “An In-depth Exploration into the World Of Aluminum Printed Circuit Boards”

Introduction:

Welcome aboard this enlightening journey where we delve deep into understanding all aspects surrounding one fascinating piece of technology – Aluminum PCB the Aluminum Printed Circuit Board (PCB). When it comes to manufacturing superior-quality circuits that can withstand high temperatures while maintaining unmatched durability and efficient thermal management, Aluminum PCBs emerge as the ultimate solution.

Manufacturing Process:

The manufacturing process of Aluminum PCBs involves intricate steps to bring together aluminum substrates and copper layers. By combining heat, pressure, and chemical etching techniq IMS (Insulated Metal Substrate) PCB ues, these innovative boards are fabricated with precision.

Features Aluminum PCB :

One noteworthy feature that sets Aluminum PCBs apart from their counterparts is their exceptional thermal conductivity. The ability to effectively dissipate heat grants them a significant advantage in high-power applications where temperature management poses a challenge. Additionally, the robust construction ensures excellent mechanical strength.

Advantages:

Utilizing Aluminum PCBs offers numerous advantages over conventional FR4 boards. Enhanced heat dissipation capabilities translate into increased reliability and MCPCB (Metal Core Printed Circuit Board) prolonged lifespan for electronic devices operating under extreme temperatures. Moreover, the lightweight design facilitates compact product form factors without compromising on performance or durability. Furthermore, the low thermal expansion coefficient exhibits remarkable stability even when exposed t

o diverse temperature variations.

Applications:

Aluminum Printed Circuit Boards find extensive usage across various industries requiring reliable circuitry with superior thermal handling capabilities – whether it be high-powered LED lighting products or automotive engineering solutions demanding optimal heat dissipation for enhanced safety measures.

Usage Guide:

To make sound decisions regarding your choice of an Aluminum PCB provider,

Proper understanding of desired specifications

Careful evaluation of technical requirements

Conclusion:

In essence,

In conclusion,

Ove Multilayer PCB rall,

These snippets demonstrate how Aluminum PCBs have revolutionized electronic circuitry with their intrinsic qualities such as unmatched thermal conductivity, mechanical resilience, and w

eight efficiency. Choosing the right manufacturer who can cater to specific needs ensures seamless integration into any project while unlocking its full potential for innovation-driven ventures worldwide.