Alloy Steel Plate: Manufacturing, Chara alloy steel plate cteristics, Advantages, and Selection Guide

Introduction:

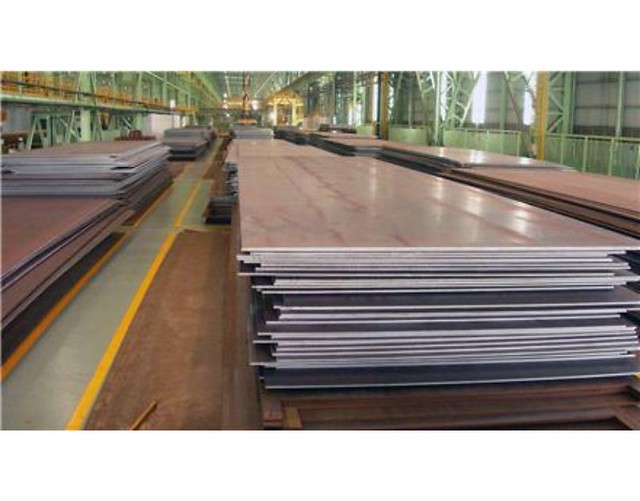

In the world of construction and manufacturing industries, alloy steel plate is widely used for its exceptional strength and durability. This article explores the manufactur

ing process of alloy steel plates, highlights their characteristics and advantages, provides guidance on how to select the right product for specific applic Alloy Sheet ations.

Manufacturing Process:

Alloy steel plates are manufactured through a complex process that involves blending different types of metals to create an optimal combination w alloy steel plate ith desired properties. High-quality raw materials such as iron ore, nickel, chromium, vanadium are melted in furnaces at high temperatures to form a molten mixture. This molten metal is then poured into molds or rolled between heavy rolle alloy steel plate rs to shape it into flat sheets or panels. The resulting alloy steel sheet undergoes vari alloy steel plate ous treatments such as heat treatment and mechanical processes to enhance its hardness and toughness.

Characteristics:

Composite steel plates exhibit several distinct characterist Composite steel plate ics that make them suitable for diverse industrial applications. These include:

– Exceptional strength: Alloy steel plates possess superior tensile strength compared to traditional carbon steel Alloy Sheet s.

– Corrosion resistance: Due to the presence of elements like chromium and nickel in their composition,

these plates display excellent resistance against corrosion caused by exposure to moisture or Alloy steel sheet harsh environments.

– High temperature resistance: Alloy steels can withstand elevated temperatures without losing their structural integrity.

– Wear resistance: These plates off Blend steel plate er excellent resistance against wear due t