Adhesive Glue

Adhesive glue is a substance used for joining two surfaces together in a semi-permanent to permanent bond. It is widely used in many industrial applications.

The adhesive bonds to the substrates it is applied to primarily through intimate intermolecular contact. Attainment of this contact results in the generation of a number of attractive forces, including chemical bonds and van der Waals forces.

Water-based

Water-based adhesive glues are one of the most popular options for labeling consumer packaging. They increase line speed and minimize material waste, while still allowing for flexible bonding. They are environmentally friendly and do not release toxic fumes or VOC.

There are many types of water-based adhesives, which range in strength and chemistry, but they all have a common feature: they form a bond between substrates using a combination of dissolved polymers and other additives. They are available as solutions or in dry powder forms that must be mixed with water prior to use.

The most common type of water-based adhesive is the dispersion/emulsion system, which includes a large number of polymers. These include vinyl acetate and copolymers, ethylene vinyl acetate, polyacrylates, natural rubber latex, and synthetic elastomers.

Adhesive dispersions are heterogeneous mixtures of a liquid or solid polymer phase in an aqueous phase, often referred to as “white glue”. They can be applied by brush, roller, spray or in beads, and have an open time that can range from minutes to days depending on the formulation. They are primarily used in manual applications but also are widely used in manufacturing processes.

Unlike solvent-based glues, water-based adhesives can be diluted on the production line and are generally easier to handle. This is facilitated by on-line dilution systems, which eliminate the need for heavy lifting and dumping pails.

Another important factor to consider is temperature, as a water-based adhesive should be stored in a cool place at least 7 days before use. This is especially true when used at a high rate, such as on high volume adhesive spraying equipment.

As an alternative to traditional solvent-based glues, water-based glues are gaining popularity in the paper packaging industry as a more sustainable option for on-the-go packages and paper containers. They are easy to apply, increase line speed, and minimize material waste.

Water-based adhesives are a great solution for a variety of applications in the furniture and woodworking industries, as well as for paper labeling. They are a good choice for flat lamination, finger jointing and tongue-and-groove joining, and can be applied by hand or automatic equipment.

Solvent-based

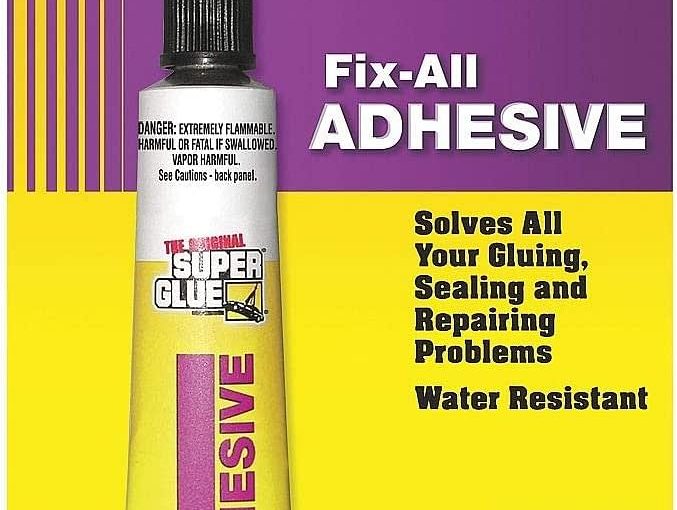

Solvent-based adhesive glues are commonly used across the packaging, tapes and medical industries due to their high resistance to environmental factors and their suitability to a wide variety of substrates. They are particularly useful for bonding to porous surfaces, but can also be applied to non-porous ones.

They also have better temperature stability than solvent-free adhesives. This means that they are less likely to degrade or discolour when exposed to varying temperatures, so they can be applied to different substrates over a long period of time.

These adhesives are a popular choice in the manufacturing of transdermal and drug delivery products because they offer a strong and secure hold that persists even when they come into contact with other chemicals or solvents.

However, they can be toxic and flammable, so you need adhesive glue to ensure that you use them carefully. They are also known to release a lot of volatile organic compounds (VOCs), which can contribute to global warming and cause other environmental problems.

There are many ways to avoid exposure to these toxins, such as working in a well-ventilated area and using an inert gas during application instead of compressed air. In addition, make sure to follow any specific instructions your manufacturer provides and never work near flammable items or materials.

You should also be aware that these glues may not dissolve in water, so it is important to remove them from surfaces before they have dried completely. This can be tricky and can leave behind a residue, so it is best to use a removal solution to get rid of the glue.

As a result of the growing interest and consciousness towards environmental responsibility, new technologies have been developed to reduce or eliminate the use of solvents in adhesive systems. These include solvent free glue, hot melt and high solids adhesives as well as waterborne systems.

Adhesives with solvents

Adhesive glues that contain solvents are used for a variety of different purposes. Some of them are designed to bind together materials, while others are meant to be used as a paint stripper.

Some of these adhesives can be quite dangerous, so it’s important to know what you’re doing before you use them. Some of them are flammable, so it’s also important to know if your area is safe from fire (especially if you’re working with children).

Solvent-based adhesives are a common choice for some industrial applications because they are easier to apply than water-based glues. They can be sprayed or brushed on, and are often available at hardware stores.

They are a good choice for bonding a range of different materials, including plastics, metals and woods. They are also strong and durable, making them suitable for long-term use.

These adhesives are often based on a polymer that is mixed with a solvent and then sprayed onto a substrate. Once the adhesive glue solvent has evaporated, the adhesive will start to harden.

Another popular type of solvent-based adhesive is contact adhesive. They are made from a polymer mixed with organic solvents, and they are usually applied to both surfaces before they are bonded together. The two surfaces are allowed to dry out for a short period of time before they are pressed together.

In some cases, contact adhesives can be cross-linked, which can increase the strength of the bond. This can be especially useful in situations where the bonded areas are subject to heat or moisture.

The chemicals used in these adhesives can also be toxic, so it’s important to take all necessary safety measures when using them. Some of them can cause a serious amount of damage to skin and eye, so it’s always a good idea to wear protective clothing when working with them.

There are a wide variety of solvent-based adhesives available, so it’s important to choose the right one for your application. These are great for bonding a range of different materials, but you should be careful when using them, so make sure to check the label to ensure you’re applying the right type to your material.

Adhesives without solvents

Adhesives without solvents are a great option for those who need an adhesive that is safer for the environment and their health. They are also cheaper to use and have less waste than their solvent-based counterparts.

There are many types of solvent-free adhesives that can be used for a variety of different purposes, including water-borne dispersion and hot melt glues. They are a great choice for projects that require a high bond strength, as they are easy to work with and will cure quickly.

Some of these solvent-free adhesives are formulated to bond a wide range of materials, and can be used for both indoor and outdoor applications. They are ideal for sealing glass, sanitary fittings, showers and skirting boards.

The best way to determine whether an adhesive is solvent-free is to read the label or packaging. This will tell you the type of solvents used in the glue and how they are absorbed by the material.

Another factor that is important to consider when choosing an adhesive that does not contain solvents is the open time. This is the time it takes for the liquid to dry, and will determine the strength of the bond.

It is also important to note that solvent-based adhesives can be flammable and toxic, which means that they should not be handled in a way that could cause injury. This includes working in a well-ventilated area and wearing a safety mask.

Solvent-based adhesives are used in a variety of industries, such as shoe manufacturing, the automotive industry and furniture construction. They are also common in printing and textiles.

One of the main problems with these types of adhesives is that they can be difficult to remove, even if you have cleaned the area where the adhesive was applied. This is because the chemical structure of these adhesives can be quite different from the material that was originally applied to.

In addition, the adhesive may have a strong bond to the material that was initially applied, which can be difficult to remove. This can also result in the glue sticking to the skin and potentially causing an infection or other medical problems.