Steel Pipe/Tube: Manufacturing, Characteristics, Advantages, Usage, Selection Tips and Conclusion

Steel Pipe/Tube

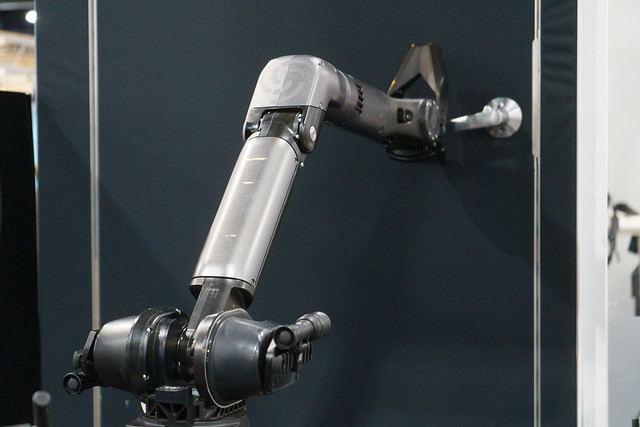

Metal pipe/tube, Seamless steel cylinder, Carbon steel casing

Steel Pipe/Tube, Steel Pipe/Tube Alloy Sheet…

Manufacturing:

The manufacturing process of Carbon steel casing steel pipes/tubes involves several steps. It starts with the raw materials selection which mainly includes carbon or alloy sheets. These sheets are then heated to a high tem Alloy Sheet perature to form a cylindrical shape using various methods like extrusion or rolling. The formed tubes are further treated for strength and durability before being cut into desired lengths.

Characteristics:

Steel pipes/tubes have severa Steel Pipe/Tube l distinguishing characteristics that make them highly popular in various industries. Firstly, they possess excellent strength and toughness due to their composition. Secondly, they exhibit exceptional resistance against c Alloy Sheet orrosion and extreme temperatures. Additionally, seamless steel cylinders provide increased reliability as they do not have any welded joints that could weaken the structure.

Advantages:

The use of steel pipe/tube offers numerous advantages over other materials in different applications. One significant advantage is its ability to withstand high pressure an Steel Pipe/Tube d heavy loads without deformation or failure. Moreover, these products provide excellent resistance to chemicals and have longer service life compared to other options on Steel Pipe/Tube the market.

Usage:

Due to their versatility and superior performance characteristics,

steel pipes/tubes find extensive usage across multiple industries.

For instance,

in the construction sector,

they are widely employed for structural purposes such as columns and support beams.

In oil and gas industry,

these pipes carry fluids over Metal pipe/tube long distances during extraction or transportation.

Furthermore,

steel tubes play a crucial role in conveying water supply for residential as well as agricultural purposes.

Their use extends ev

en further into industries like automotive,

aerospace,

and telecommunications.

Selection Tips:

While choosing steel pipes/tubes for a specific application,

it is important to consider certain factors:

1) Required specifications:

Evaluate your project requirements regarding dimensions,

strength,

pressure rating,

and any specific certi Steel Pipe/Tube fications necessary.

2) Corrosion resistance:

Assess the environment where the pipes/tubes will be used to select appropriate corrosion-resistant coatings or alloys.

3) Cost-effectiveness:

Consider the upfront and long-term costs associated with different types of steel pipes/tubes, including installation,

maintenance,

and potential repairs.

Conclusion:

S Seamless steel cylinder teel Pipe/Tube is a versatile and reliable product widely used in various industries due to its excellen

t strength, durability, and resistance against corrosive environments. The manufacturing process involves selecting high-quality carbon or alloy sheets and shaping them into cylinders through processes like extrusion or rolling. The wide range of applications highlights their effectiveness in fulfilling diverse needs. To ensure optimal performance and longevity, careful consideration should be given while selecting these products based on pro

ject requirements, corrosion resistance, and cost-effectiveness.