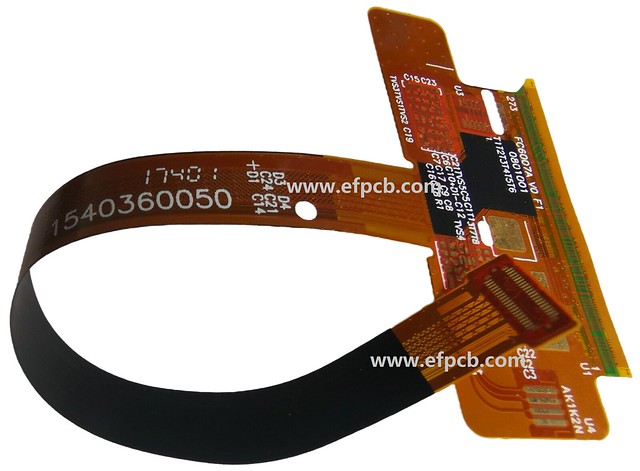

Flexible PCB: A Versatile Solution in Electronic Circuitry

Introduction:

The world of electronics is constantly evolving with the demand for smaller and more flexible devices. One key component that enables this innovation is the Flexible Printed Circuit Board (PCB). In this article, we will PCB manufacturer explore the manufacturing process, characteristics, advantages, usage methods, tips on selecting these boards and draw a conclusion on their significance in the industry.

Manufacturing Process:

Flexible PCBs are made using advanced processes that differ from traditional rigid circuit boards. These circuitry marvels are enabled through various techniques such as additive c High Frequency PCB opper deposition and high-resolution laser ablation. The flexibility of these boards allows them to be bent or folded without compromising their functionality.

Characteristics:

Flexible electronic circuit boards offer unique features that make them highly desirable in modern electronics:

1. Bendable printed circuitry: The ability to

bend or flex makes it possible to fit into tight spaces where traditional rigid PCBs would fail.

2. Elastic printed wiring board: Due to its elasticity, these PCBs can withstand vibrations and shocks better compared to traditional counterparts.

3. Bendable PCB: This characteristic ensures durability even under repeated bending cycles which expands their lifespan significant Rigid-flex PCB ly.

4. Flex PCB Manufacturing Material: Since they’re primarily built using polyimide film materials instead of FR-4 laminate like rigid ones possess an advantage in terms of weight reduction.

5.

High Frequency Performance: Many flexible manufacturers also specialize in creating high-frequency designs suitable for applications requiring faster signal transmission.

Advantages:

There are several advantages associated with implementing flexible circuits:

1.Flexibility enhances design possibilities by allowing complex layouts that conform to device contours.

2.It reduces assembly time thanks to fewer interconnection points required between separate modules due to reduced size/volume

3.Improved electrical performance due shorter conductive p Flexible electronic circuit board aths resulting low resistance/inductance value

4.Easy integration within curved environments e.g., Smartphones wrapped screens etc

Usage Methods:

Flexible PCBs find their util Elastic printed wiring board ity across various industries including:

1. Consumer Electronics: Smartphones, tablets, wearables primarily rely on flexible circuit boards to ensure efficient utilization of limited space without compromising performance.

2. Medical Devices: Advanced medical equipment such as implantable devices and diagnostic tools require flexibility to enable comfort for patients while maintaining accuracy in the readings.

3. Aerospace industry: The lightweight nature and resilienc Flexible PCB e offered by these bendable circuits make them ideal for aerospace applications.

How to Select Flexible PCBs:

When choosing a manufacturer or supplier for flexible circuitry needs, consider the following parameters:

1. Experience: Look for a manufacturer with years of experience in producing flexible PCBs as it ensures quality and reliability.

2. Material Quality: Ensur Flexible PCB e that they use high-quality materials like polyimide films and adhesive layers that meet industry standards.

3.Customer Support: Availability of technical support through all stages – from design consultancy to post-production support – is crucial.

Conclusion:

In conclusion, Flexible PCBs are revolutionizing electronic designs with their ability to conform around irregular shapes while maintaining performance standards catering to modern requirements seamlessly. Their unique features offer unparalleled o Flexible PCB pportunities in design layouts and improvements in assembly time resulting superior efficiency throughout electronic products’ lifecycle.

As technology advances further into miniaturization, the demand for Flexibles continues rising Higher Frequency sig Bendable printed circuitry nals growing importance contributing towards new age challenges integrating reliability-rich solutions within flexible domain becomes necessary! Choose wisely when selecting your manufacturing partner!