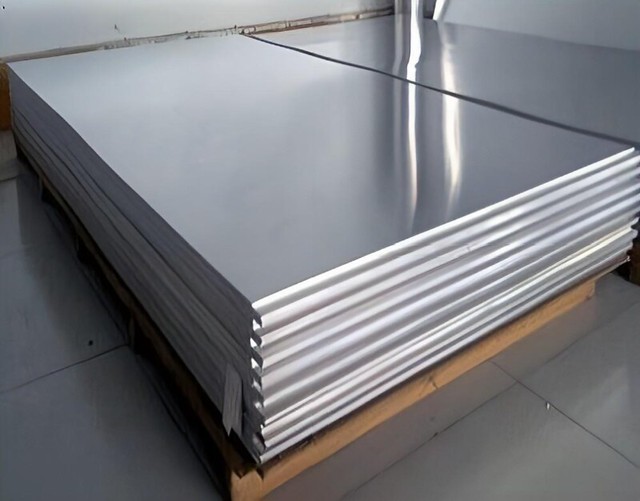

Article Title: Alloy Steel Plate – The Ultimate Guide for Manufacturing, Characteristics, and Selection

Alloy steel plate is a versatile product widely used in various industrial applications. It offers exceptional strength, durability, and corrosion resistance compared to regular steel plates. In this article, we will explore the manufacturing process of alloy steel

plate, its characteristics, advantages, usage methods, tips for selecting the right product, and conclude with key takeaways.

Manufacturing Process:

Alloy steel plates are primarily made through two main processes: hot rolling and cold rolling. Hot rolling involves hea alloy steel plate ting metal above its recrystallization temperature and passing it between large rollers until it reaches the desired thickness. Cold rolling follows a similar procedure but at room temperature which further enhances strength by compressing the structure.

Characteristics:

Alloy steel plates possess several uniq Alloy Sheet ue characteristics that make them highly sought after in various industries. Firstly, they exhibit excellent tensile strength due to the addition of alloying elements like chromium or nickel. Secondly, their high hardness levels ensure exceptiona Composite steel plate l wear resistance even in harsh conditions.

Advantages:

The use of alloyed materials provides numerous advantages for those working with these plates. One of the key benefits is increased resistance to corrosion caused by environmental factors such as moisture or chemicals. Additionally, alloy steel plates offer improved weldability which allows for easier fabrication during assembly processes.

Usage Methods:

Mixed metal sheets find extensive applications across different sectors including con alloy steel plate struction sites where they serve as structural supports due to their superior load-bearing capacity. Composite steel plates are often utilized in automotive manufacturing where lightweight yet sturdy materials are required; this helps enhance fuel efficiency without compromising safety standards.

Compound alloy panels have gained popularity within aerospace industries thanks to their ability to withstand extreme temperatures while maintaining dimensional stability.

Fusion steel sheets combine multiple metals resulting in enhanc alloy steel plate ed mechanical properties making them ideal for specialized machinery or infrastructure projects.

Steel alloy panels offer an optimal balance between strength and weight making them suitable for marine applications such as shipbuilding and offshore Mixed metal sheet structures.

How to Choose the Right Alloy Steel Plate:

When selecting an alloy steel plate, several factors must be considered. Firstly, the intended application must be carefully assessed to determine the necessary strength and corrosion resistance requirements. Additionally, consider the environment in which it will operate; if exposure to extreme temperatures or harsh chemicals is expected, choose a plate with superior resistance properties. Finally, analyze fabrication requirements including weldability and forma Alloy Sheet bility to ensure smooth integration into your project.

In conclusion, alloy steel plates are essential components in various industries due to their exceptional strength, durability, and resistance properties. Compound alloy panel The manufacturing process involves hot rolling or cold rolling techniques resulting in a range of characteristics that meet diverse commercial needs. Their advantages include improved corrosion resistance and weldability compared to regular steel plates.

By following appropriate selection criteria based on the application’s demands and considering important factors like environment and fabrication requirements,

one can easily i alloy steel plate dentify the most suitable alloy steel plate for their project.

Remember – alloy steel plates are key solutions when demanding robustness meets high-performance standards!