Alloy Steel Sheet: Manufacturing, Features, Advantages, and Selection Criteria

Introduction:

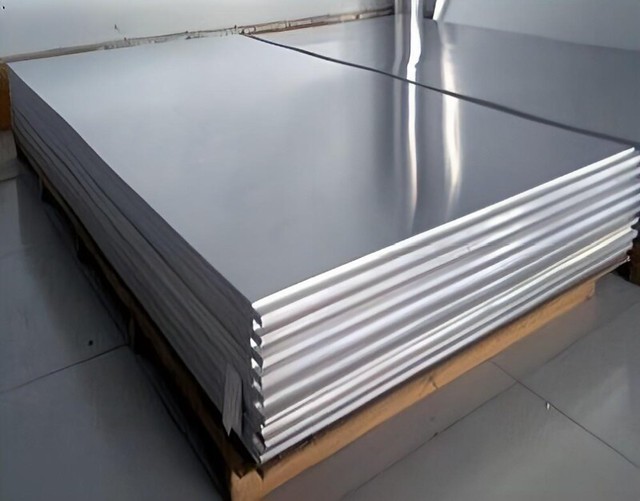

Alloy steel sheet is a versatile material used in various industries for its exceptional properties. This article will discuss the manufacturing process, alloy steel sheet features, advantages, usage methods of alloy steel sheets, and provide guidelines for selecting the right product.

Manufacturing Process:

The production of alloy s carbon steel manufacturer teel sheets involves blending different metals to create a high-performance material. Carbon steel manufacturers play a crucial role in this process by combining specific alloys with carbon steel. The blended mixture is then heated at extreme temperatures before being rolled into thin sheets.

Features:

1. St Mixed metal sheet made with alloys rength and Durability: Alloyed steel panels are known for their excellent strength-to-weight ratio. They can withstand heavy loads without deforming or breaking.

2. Corrosion Resistance: Mixed metal sheets made with alloys exhibit superior resistance to corrosion caused by moisture or chemicals.

3. Heat Resistance: Alloy steel sheets can resist high temperatures without losing their structural integrity.

4. Versatility: These sheets offer versatility regarding shapes and sizes due to their malleabil

ity.

Advantages:

1. Enhanced Performance: The unique combination of metals in alloyed steels enhances their mechanical Alloyed steel panel properties offering better performance compared to traditional materials like carbon steel.

2.Higher Load Capacity: Alloyed steels have greater load-bearing capacity than plain carbon or stainless steels making them suitable for demanding applications such as construction equipment or pressure vessels.

3.Cost-Efficiency: Although alloy steels may be more expensive upfront, they offer long-term cost savings due to their durability and resistance to wear and tear.

4.Wide Range of Application Alloy steel plate s :Blend Steel Sheets find application in automotive industry (chasis), machinery components(saw blades) , shipbuilding(seafaring vessels), aerospace sector(fuselages)

Usage Methods:

1.Machining & Fabrication – Due to its malleability ,alloyed Steels can be machined into carbon steel manufacturer intricate shapes and sizes.

2.Joining – Alloyed steel sheets can be welded or soldered to create structurally sound assemblies.

How to Select the Right Product:

1.Application Specific: Identify your specific application needs and choose alloy steel sheets that offer the required alloy steel sheet strength, corrosion resistance, or heat resistance for optimal performance.

2.Certifications: Look for reputable manufacturers who provide certified alloy steel sheets tested according to industry standards such as ASTM (American Society for Testing and Materials).

3.Consult Experts : When in doubt, consult experts or engineers with expertise in material selection.

Conclusion:

Alloy steel sheet is alloy steel sheet an indispensable material known for its exceptional mechanical properties. Its versatility, superior strength, durability against corrosion and higher load capacity make it a preferred choice across industries. By understanding the alloy steel sheet manufacturing process, features, advantages, usage methods, and following the selection criteria mentioned above one can ensure choosing the right product best suited for their application-specific requirements.