Galvani Zinc-coated Coil/Sheet zed Coil/Sheet: Manufacturing Process, Features, Advantages, Usage Methods, How to Choose the Product, Conclusion.

Introduction:

Galvanized coil/sheet is a widely used material in various industries for its durability and corrosion resistance. In this article, we will explore the manufacturing process of galvanized coil/sheet along with its features, advantages, usage methods, and tips on how to choose the right product for your needs.

Manufacturing Process:

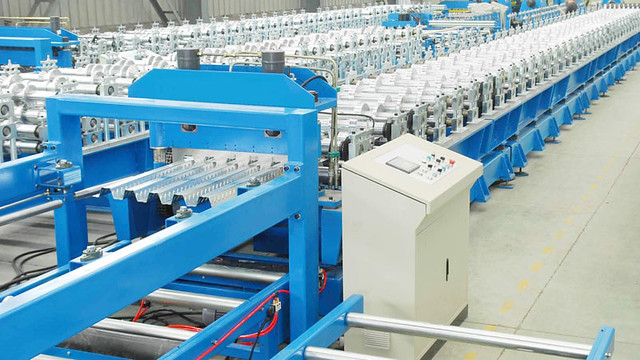

Galvanized coil/sheet is made by Galvanized Coil/Sheet immersing steel into a bath of molten zinc at a high temperature. The steel substrate reacts with the molten zinc to form a series of alloy layers that adhere tightly to the base metal. This process is known as hot-dip galvanizing. Additionally, electro-galvanized coil/sheet can be produced by electrolysis deposition method using an electric current.

Fe

atures:

1. Corrosion Resistance: Galvanized coating protects the underlying steel from rust and corrosion.

2. Durability: The additional layer of Galvanized Coil/Sheet zinc provides excellent durability and longevity.

3. Versatility: Galvanized coil/sheet can be easily formed into various shapes without compromising its integrity.

4. Cost-Effective: It offers long-term cost savings due to minimal maintenance requirements.

Advantages:

1. Protection Against Rust: Galvanized c Galvanized Coil/Sheet oatings act as a barrier against moisture and corrosive elements.

2. Wide Range of Applications: Galvanized metal is used in automotive parts, construction materials, household appliances,and more.

3.Increased Strength:The combination of steel strength and a protective layer makes it highly resistant to damage caused by impact or abrasion.

Usage Methods:

1.Roofing & Wall Cladding:The galvanized sheet acts as Galvanized Coil/Sheet vital protection against weather conditions such as rainwater or snowfall .

2.Automotive Industry:Used extensively in automobile bodies , panels , frames due to their exceptional corrosion resistance properties

3.Construction & Infrastructure:Galvanized steel is used in s Metallic Coated Coil/sheet tructural beams, support columns, fences, guardrails

4.HVAC: Galvanized ductwork systems are widely used in heating, ventilation,and air conditioning installations for their corrosion resistance.

How to Choose the Product:

When selecting a galvanized coil/sheet for your project or application, consider the following factors:

1. Coating Thickness: Ensure that the product meets the required coating thicknes stainless steel plate supplier s specifications.

2. Zinc Density: Higher zinc density provides better protection against corrosion.

3. Surface Finish: Look for smooth and uniform surfaces without any visible defects.

4. Quality Certification: Check if the manufacturer has relevant quality certifications like ISO 9001.

Conclusion:

Galvanized coil/sheet is an essenti

al material with excellent properties such as corrosion resistance and durability.Galvanizi stainless steel plate supplier ng process adds additional protective layer onto steel substrates which enables wide range of applications across various industries.By considering specific requirements like coating thickness,zinc density and surface finish during product selection , one can ensure a reliable performance over its service life.Therefore,it is imperative to choose quality galvanized coil / sheet p Prepainted Steel Coil/sheet (with additional layer of paint) roducts from trusted suppliers ensuring higher level of customer satisfaction by avoiding potential issues related to sub-standard coatings or protective performances .