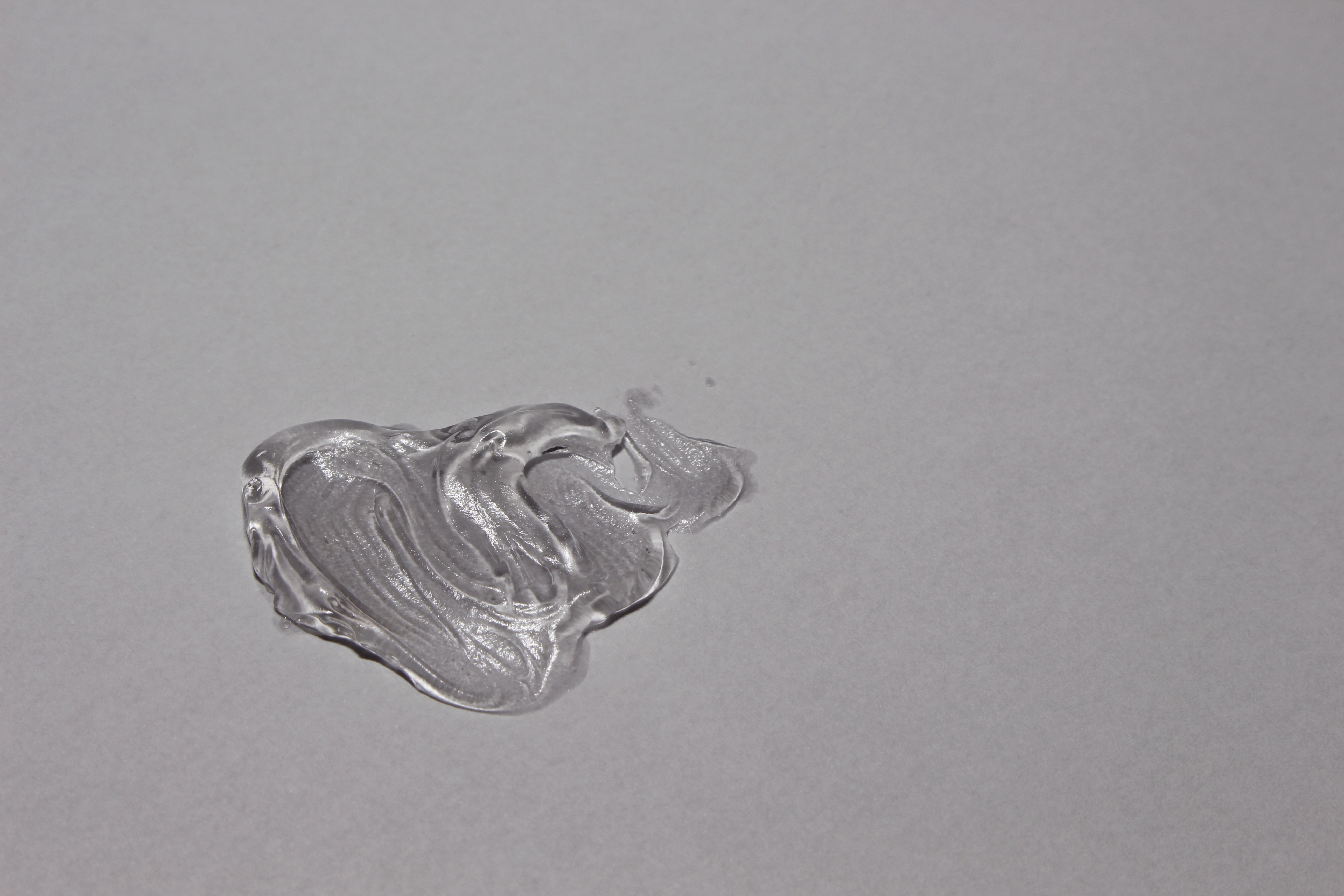

Quality Silicone Sealant for Various Applications

Welcome to our blog post on quality silicone sealants for various applications! Whether you’re a DIY enthusiast, a professional contractor, or simply someone looking to tackle some household repairs, silicone sealant is an essential tool in your arsenal. With its versatility and durability, it’s no wonder that silicone sealant has become a go-to solution for sealing and bonding in numerous industries.

In this article, we’ll delve into the world of silicone sealants – what they are, the different types available, their pros and cons, as well as how to choose the right one for your specific needs. We’ll also explore some common applications where silicone sealants shine brightest. So let’s dive in and discover why silicone sealant deserves all the hype!

What is silicone sealant?

Silicone sealant, also known as silicone adhesive or silicone caulk, is a versatile material used for sealing and bonding various surfaces. It is made from a combination of silicone polymers and other additives to create a flexible and durable product.

One of the key characteristics that sets silicone sealant apart is its outstanding resistance to extreme temperatures. Unlike other types of sealants, silicone can withstand both high heat and freezing conditions without losing its effectiveness. This makes it ideal for outdoor applications such as sealing windows and doors, as well as for use in areas exposed to direct sunlight.

Another notable feature of silicone sealant is its excellent water resistance. Once cured, it forms a watertight barrier that prevents moisture from seeping through cracks or gaps. This makes it perfect for bathroom renovations where waterproofing is crucial or for repairing leaks around sinks, showers, or plumbing Silicone Sealant fixtures.

Furthermore, silicone sealant offers great adhesion properties on various materials including glass, metal, plastic, ceramic tiles, wood, and more. Whether you’re working on indoor projects like installing baseboards or outdoor tasks like fixing gutters or roof flashing – silicone sealants provide strong bonds that are long-lasting.

Additionally,

silicone sealants come in different colors to match your aesthetic preferences,

they are resistant to mold and mildew growth,

and they can even be paintable once fully cured!

Overall,

silicone sealant’s unique properties make it an invaluable tool for countless applications across multiple industries.

So whether you’re tackling home improvement projects or working in professional settings – having quality silicone sealant on hand will undoubtedly save you time and effort!

Different types of silicone sealant

Different types of silicone sealants offer diverse properties and are designed for specific applications. Each type has its own unique characteristics that make it suitable for various sealing requirements.

One type of silicone sealant is the acetic cure silicone sealant, also known as acid cure. This type releases acetic acid during the curing process, giving off a strong vinegar-like odor. It has excellent adhesion to glass, ceramic, and porcelain surfaces but should not be used on metals or painted surfaces due to its corrosive nature.

Another type is the neutral cure silicone sealant. This variety does not release any corrosive by-products during curing and is therefore safe to use on most substrates including metal, plastic, and painted surfaces. Neutral cure silicones are often preferred for indoor applications where odors can be a concern.

There are also specialized silicone sealants such as high-temperature resistant variants that can withstand extreme heat without compromising their sealing performance. These are commonly used in automotive engines or industrial settings where there is exposure to elevated temperatures.

For more specific needs, there are also specialty formulations like sanitary grade silicone sealants designed specifically for kitchen and bathroom applications where mold resistance is crucial.

Choosing the right type of silicone sealant depends on factors such as substrate compatibility, environmental conditions, and application requirements. Always ensure you select a product that meets your specific project needs to achieve optimal results in both functionality and longevity.

In conclusion (not applicable here), understanding the different types of silicone sealants available will help you make an informed decision when choosing one for your next project. By selecting the appropriate formulation based on its intended application and desired properties, you can ensure effective sealing solutions across various industries and environments

Pros and cons of silicone sealant

Pros and Cons of Silicone Sealant

Silicone sealant is a popular choice for various applications due to its many benefits. However, like any product, it also has its drawbacks. Let’s take a look at the pros and cons of silicone sealant.

One of the biggest advantages of silicone sealant is its durability. It can withstand extreme temperatures, making it suitable for both indoor and outdoor use. Additionally, silicone sealant is highly resistant to moisture, UV rays, chemicals, silicone sealant wholesale and mildew. This makes it an excellent choice for sealing gaps in bathrooms, kitchens, windows, and other areas prone to water damage.

Another benefit of silicone sealant is its flexibility. Unlike other types of sealants that may crack or shrink over time, silicone remains flexible even after curing. This allows it to accommodate movement without compromising the integrity of the seal.

Furthermore,… [continue writing]

How to choose the right silicone sealant

Choosing the right silicone sealant for your specific application is crucial to ensure optimal results. With so many options available, it can be overwhelming to make the right choice. Here are some factors to consider when selecting a silicone sealant.

You need to determine the purpose of the sealant. Is it for interior or exterior use? Will it be exposed to extreme temperatures or direct sunlight? Understanding these requirements will help narrow down your options.

Next, consider the substrate on which the sealant will be applied. Different surfaces require different types of silicone sealants. For example, if you’re sealing glass or ceramic surfaces, opt for a clear adhesive specifically designed for those materials.

Another important factor is flexibility and durability. Silicone sealants offer varying levels of elasticity and resistance to weathering and aging. Consider whether you need a high-performance sealant with excellent adhesion and long-term durability.

Additionally, take into account any special features that may be required for your project. Some silicone sealants have added properties like mold resistance or fire retardancy, which can be beneficial in certain applications.

Always check product specifications and instructions from manufacturers before making a decision. This ensures compatibility with your intended use and provides guidance on application techniques and curing times.

By carefully considering these factors, you can confidently choose the right silicone sealant that meets your specific needs and achieves reliable performance in various applications without compromising quality or longevity

Silicone sealant applications

Silicone sealants are incredibly versatile, making them suitable for a wide range of applications. Whether you need to seal joints, bond materials together, or protect against moisture and heat, silicone sealants can get the job done.

One common application for silicone sealant is in construction. It can be used to create watertight seals around windows and doors, preventing leaks and drafts. Silicone sealant is also ideal for sealing gaps between tiles or filling cracks in concrete.

In automotive applications, silicone sealants provide excellent adhesion and resistance to high temperatures. They can be used to create gaskets and seals in engines or as an adhesive for mounting parts.

Another useful application is in electrical work. Silicone sealants offer insulation properties that make them perfect for sealing electrical connections and protecting them from moisture.

Additionally, silicone sealant is commonly used in plumbing projects. It can effectively waterproof joints on pipes or fixtures like sinks and showers.

Silicone sealant finds its place in arts and crafts projects too! It’s great for creating molds or casting objects due to its flexibility and easy release properties.

With their ability to withstand extreme temperatures, resist water damage, adhere well to various surfaces, it’s no wonder why silicone sealants have such extensive applications across different industries!

Conclusion

Conclusion

Silicone sealant is a versatile and reliable product that can be used in various applications. Whether you are sealing gaps and cracks around your home or tackling more demanding projects like automotive repairs or industrial construction, there is a silicone sealant available to meet your needs.

When choosing the right silicone sealant, it is important to consider factors such as curing time, flexibility, temperature resistance, and compatibility with different materials. By understanding these characteristics and selecting the appropriate type of silicone sealant for your specific application, you can ensure long-lasting results.

Silicone sealants offer numerous advantages including excellent adhesion properties, durability in extreme weather conditions, resistance to moisture and chemicals, as well as their ability to maintain flexibility over time. However,

it’s worth noting that they may not be suitable for every situation. It is essential to assess the pros and cons before deciding on using silicone sealant for your project.

From sealing windows and doors to waterproofing bathrooms or repairing electrical components, silicone sealants have proven themselves across a wide range of applications. Their versatility makes them an invaluable tool for both DIY enthusiasts and professional contractors alike.

As technology advances further in the field of adhesive products,

we can expect even more innovative solutions from manufacturers.

With ongoing research into improving performance

and expanding application possibilities,

the future looks promising for silicone sealants.

So next time you’re faced with a task that requires sealing or bonding,

consider using quality silicone sealants.

They offer unmatched reliability

and ensure exceptional results

in various applications!

Remember: Choose wisely; choose quality;

choose the right silicone sealant!