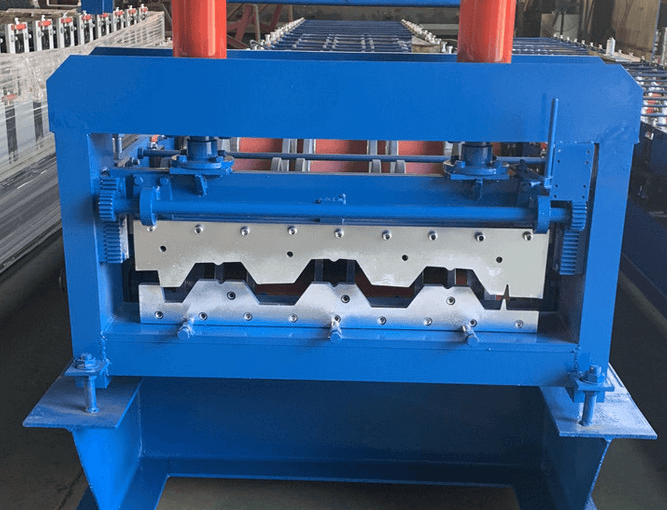

Floor Decking Roll Forming Machine

If you are looking to get a floor decking roll forming machine, you’ll want to consider some important factors. One thing you’ll want to make sure of is a good deposit. This means getting 30% of the machine’s total value before you even start the purchase.

HG series

The HG series floor decking roll forming machine is an efficient flooring production equipment. It has several special features that help improve the floor decking process. These include high-performance coil sheet equipment, post cutting ability, and an uncoiler.

Using a forming machine to form a metal deck is a great way to enhance the structural strength of a floor. The high strength-to-weight ratio of the floor deck enables easy erection and lowers the overall cost of building the floor. A well-designed metal decking floor can support concrete and an insulating membrane, providing a strong and lightweight surface.

An HG series floor decking roll forming machinery is an ideal way to ensure that the floor deck is well-constructed and sturdy. This machine integrates electrical, hydraulic, and mechanical technologies to create the perfect deck for your floor.

The HG series floor decking roll former also comes with an integrated hydraulic station, a supporting table, and an uncoiler. These are all designed to maximize the productivity of the machine while maintaining its efficiency.

In addition to the big and the little, the HG series floor decking roll forming apparatus is also optimized via computer to create the most effective floor decking. Although not as fancy as the other types of machines, the HG series is still a workhorse.

The HG series floor decking machine is the best choice for industrial and commercial applications, enabling the creation of a floor deck that is strong, sturdy, and affordable. Combined with a proper maintenance schedule, it is an asset to any company. With its superior quality and impressive performance, you can be assured that it will be an asset for years to come.

The HG series forming machine has several high-end features, including a high strand count and an improved rib design. Compared to its predecessors, the HG series offers a reduced power consumption, a more user-friendly design, and the capability to produce the perfect deck for your needs.

One of the most important functions of the HG series floor decking roll former is its ability to assemble and control multiple panels. This helps in reducing the cost of manufacturing a steel deck, and provides greater safety in the event of a fire.

Samco Machinery

Samco Machinery is one of the leading manufacturers of roll forming machines. With a pan-India presence, the company serves a large consumer base. The company offers customized roll forming machines for various industries. It also provides a range of material handling solutions.

Samco is an ISO certified organization. The company’s main products include roll forming machinery, coil-processing equipment, decoilers, presses, and hold downs. In addition, Samco manufactures h beam welding machine, racking systems, and shelving & storage.

Its products are sold in 34 countries worldwide. Samco’s products are used for producing roofing panels, flooring, and more.

The company has developed a line of high-efficiency roll-forming shake tile lines. They feature new controllers and are built for accuracy and longevity. The machines can be powered by hydraulic or electric. Besides, they are designed for ease of operation and consistency.

The Acu-Form Panel Lines are manufactured with D2 tool steel for precision parts floor decking roll forming machine and long life. These lines are built to produce custom parts, saving time and money.

HG series forming machines are designed for simple construction and lower power consumption. They have a stable performance and are suitable for medium and large-scale industrial buildings.

During production, the parts are embossed. These are then sheared to the desired length. This makes the surface smooth.

The Acu-Form Panel line features a flying cut-off press, which reduces production downtime. The cut-off length can be +/- 0.0625 inches. Moreover, the cut-off can be controlled in a closed loop. This allows for small tolerances.

As an exporter of Roll Forming Machinery, Samco is known for quality assurance. Its warranty is 24 months after the client receives the product. Moreover, its products are available in bulk.

For more information about the company and its products, visit the company website. You can also contact them via telephone or email. Besides, they have an extensive network of customers around the world.

In addition to being an expert in the industry, Samco has a strong commitment to innovation and customer service. Their goal is to provide superior North American technology at competitive prices. Moreover, they have created floor decking roll forming machine a video that highlights the major suppliers of the PEB industry.

Getting a 30% deposit for a floor decking roll forming machine

A metal decking roll forming machine can be found at a fraction of the price you’d expect to pay for a similar service. It’s also easy to use. You can even have it shipped to you in a 40ft container. The only downside is you’ll have to take the long way home. If you are in the market for a new roof deck, you’re in luck. One company that specialises in metal decking roll forming machines is LOTOS. They have one of the better customer service departments out there.

While you’re at it, do a little research and you’ll find that a few companies actually manufacture the machine, including Cunmac. Getting a metal decking roll forming machine isn’t as hard as you’d imagine, and if you’re considering a new roof deck, a quick check on LOTOS might just be in your future. After all, you want to ensure you’ll get a metal decking roll forming machine that lasts for decades to come.

Having said that, you’ll need to be sure you’re getting the best product for the best price. Luckily, LOTOS has a price match guarantee. Whether you’re looking for a steel floor decking roll forming machine, a roof decking roll forming machine, or a roof decking machine of any type, LOTOS is your man. Using their patented steel decking roll forming machine, you’re sure to reap the benefits of a top quality steel decking roll forming machine. Plus, they have a full line of roof decking machines to cover every budget. Besides, LOTOS makes all of the major components for each roof decking machine, so you’re assured of getting a top-notch roof decking machine at a competitive price.

Hopefully, LOTOS’ newest metal decking roll forming machine will keep your project on track and on budget. A metal decking roll forming machine will be a great addition to your construction arsenal, and will make the job a lot easier for you.

Main parts of a floor decking roll forming machine

There are several different types of floor decking roll forming machines. They all come with their own advantages and disadvantages. You may want to consider a few different options before you choose the one that will work best for your project.

One of the main advantages of using a floor decking roll forming machine is that it is extremely durable. This means that it can be used on a large number of projects. It is also resistant to corrosion.

Another advantage is that it is extremely efficient. A single roll forming machine can produce a variety of shapes and sizes. The process is very simple. The metal is rolled on a set of guiding devices. These allow the sheet to be cut and shaped at the end of the process.

The process is automated, so the productivity can be high. Because the tooling is reused for any length, it is possible to reduce production time. With this type of rolling machine, you can also use a post-cut die to add features to the part.

Another benefit of a metal decking roll forming machine is its low cost. This allows you to save on material costs. Also, it is very easy to operate. Unlike other types of metal working machines, roll forming does not require you to heat up the metal. And the process will also reduce your energy costs.

When you’re selecting a roll forming machine, you should consider the strength, speed, and synchronization of the system. If you’re going to be working with a lot of material, you’ll want to make sure that your machine can handle it.

The roll forming machine will also help you produce more consistent products. This is because it eliminates die marks and provides clean contours. Additionally, it can be shaped to a wide range of metals. Even painted and coated metals can be formed.

Most of the roll forming equipment is able to produce parts that are at least 0.125 inches thick. In addition, the process can be adapted to produce parts that are a width of up to 20 inches.